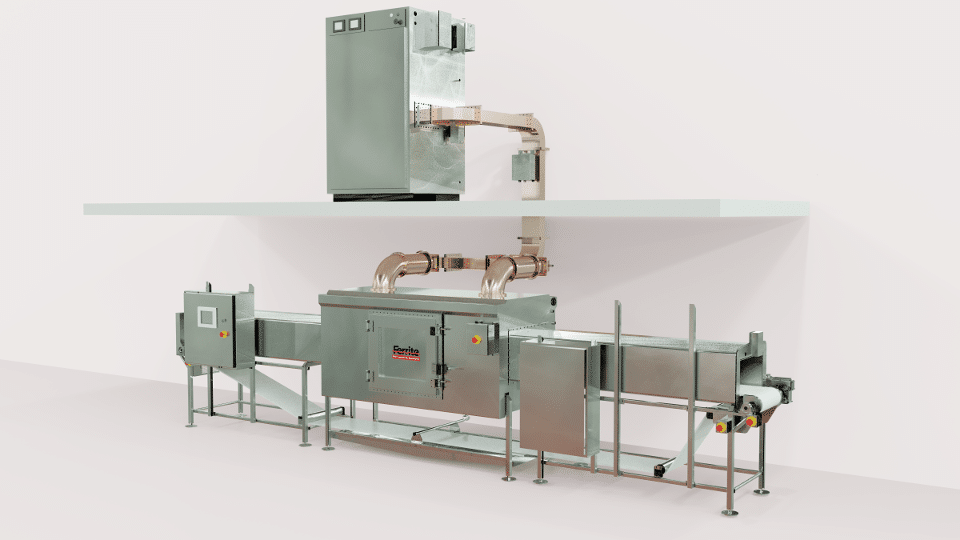

FMT’s Microwave Tempering Tunnel Oven System (MIP12) is our flagship continuous tempering system for industrial microwave food processing. Backed by precise temperature control, you can greatly reduce tempering time for seafood, frozen meat, poultry, fruits, and bakery products. Take your production time from days to minutes with the MIP12.

Microwave Tempering Tunnel Advantages

The MIP12 Microwave Tempering Tunnel offers users the ability to precisely control their product temperature. As a result of a more controlled and stable temperature increase, coupled with predictable final temperature capabilities, MIP12 users will experience more flexibility in their production processes.

Other advantages to utilizing microwave tempering tunnel ovens include:

- Preservation: drip loss significantly minimizes

- Product improvement: better quality and higher total yield

- Streamlined production: Eliminates the need for tempering rooms or racks

- Smaller footprint: savings in space and time spent travelling to and from rooms

- Promotes cleanliness: conventional processes result in sanitation issues for your facility, staff, and products

- On-demand: adds flexibility by facilitating tempering on demand, aiding in cash flow and inventory management

- Safety enhancement: by utilizing a tempering tunnel, there are fewer handling sequences, and less risk of injury

- More control: enables precise control of product temperature for next steps (i.e. dicing, grinding, forming, slicing)

Standard Microwave Tempering Tunnel Oven Specifications

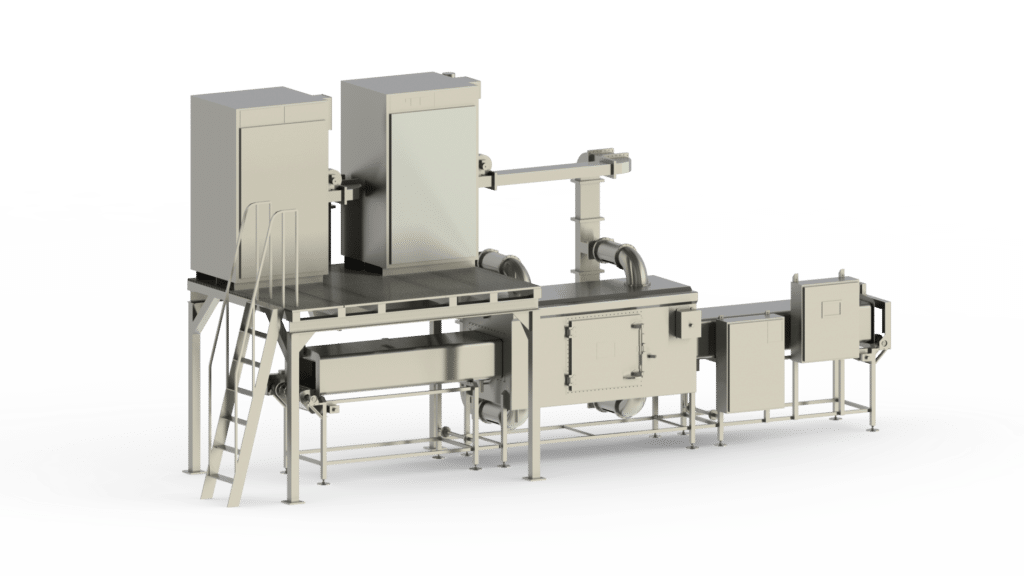

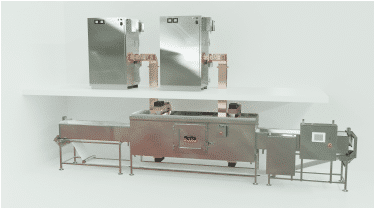

Ferrite Microwave Technologies standard MIP12 system consists of a single 4-foot by 4-foot by 8-foot long tunnel (1.2 meters by 1.2 meters by 2.5 meters) with up to four dependable 75 kilowatt microwave generators.

Product temperature control is maintained with simple belt speed or generator power adjustments. Additional generators, up to a total of four, can be added to the unit to significantly increase production output.

The standard MIP12 meets the requirements of a broad range of product applications. However, Ferrite Microwave Technologies also offers custom system layouts designed to adapt to specific customer requirements.

Why Choose the MIP12?

The MIP12 simplifies the food tempering process. It eliminates tempering rooms and racks, along with the resulting sanitation issues and brings precision to your food processing procedures. Microwave tempering gives control over the production process and helps plan both input and output production on a daily, weekly or monthly basis. Product quality and yield are improved and drip loss is minimized. Flavor and protein compounds remain in the product and are passed along to the consumer. Controlled temperature increase and predictable final temperature ensures processing flexibility.

Tempering Tunnel Ovens: FAQs

We’ve compiled a short list of frequently asked questions. To help you better understand our products, we’ve provided answers to those questions below. If you find yourself still curious, please contact our support team. We’re always happy to discuss our systems, answer your questions, learn about your current process, and recommend the best solutions.

What are some unique features of the MIP12 tempering tunnel?

The MIP12 features some of the most advanced microwave system technology in today’s world. This includes: user-friendly FMT system software, Allen-Bradley controls, and remote troubleshooting capabilities, to name a few. The unit also features arc detection, emission sensors (on either end of the tunnel), and safety interlocks on the door.

Is FMT microwave system equipment safe?

Yes. As a matter of fact, it exceeds most safety standards. Our equipment conforms to safety exposure limits of 5 mw/cm² measured 5 cm away from equipment. This is twice as stringent as OSHA’s voluntary standard.

What is the general size of products that fit into the tempering tunnel?

The standard tunnel accommodates boxes 20″ x 10″ (50 cm. x 25 cm.). However, other tunnel sizes are also available.

Is the MIP12 washable?

Yes. The MIP12 ovens and microwave generators are manufactured from stainless steel. The process oven and conveyor belt are wash-down safe.

To watch a visual demonstration of the MIP12 Continuous Tempering Tunnel Microwave Oven System, please click here.

For all other questions, please contact our support team to discuss your current infrastructure and production goals.