Ferrite Microwave Technologies microwave tempering systems are used for processing deep frozen products like beef, pork, poultry, and fish. Replacing conventional processes like tempering rooms, solutions like our MIP12 microwave tempering system is capable of accomplishing the task in a matter of minutes. Our blog post on the benefits of microwave tempering is a must-read for anyone considering alternatives to tempering rooms or conventional ovens. Besides the obvious time savings, major benefits include higher protein yields, less mess, and greater energy efficiency. As the global leader in microwave tempering systems, Ferrite Microwave Technologies welcomes you to explore some of our popular solutions.

Tempering Systems

FMT’s tempering systems are widely popular microwave solutions for their ability to improve product quality, streamline production processes, and keep facilities more clean. Often times, the alternatives, such as full rooms or racks cause products to spoil. In addition, tempering rooms require physically demanding cleaning processes, as well as management. Not only do microwave tempering systems save you in terms of cost, but they’ll save you time along the way. As such, FMT systems are becoming increasingly popular.

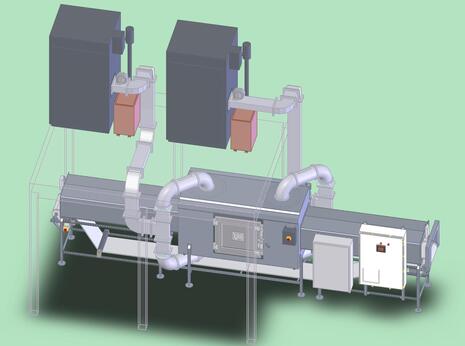

Continuous Systems

Our continuous microwave tempering systems offer users the ability to process thousands of pounds of deep frozen product per hour. These style systems enable precise control of product temperature. Once tempered, the product is ready to move further along the production line for next step processing or handling.

Custom Systems

Ferrite Microwave Technologies does extensive modeling of new applications for custom cavity development, both for ourselves and as a service to prospective customers. We are well-versed in integrating custom microwave tempering systems into existing infrastructure, and ensuring compatibility with other facility equipment.

Batch Systems

Batch processing and indexing systems are well suited for applications that involve an assortment of different products or comparatively low throughput volumes. These style systems have a much smaller footprint with less ability for larger volumes. They are ideal for fast moving production enviornments and commercial kitchens.

Microwave Tempering vs. Thawing

The advantages of microwave tempering systems stand out when compared to thawing. This is mostly due to the fact that thawing brings about problems involving drip loss, bacterial growth, and other deterioration changes. In contrast, microwave tempering vastly improves processes that come further down the production stream. This includes slicing, forming, grinding and more. When comparing microwave tempering vs. thawing, most of the advantages are connected to improved safety and health within the facility, heat balance control for the product, reduction in inventory, and overall cost savings.