Ferrite Microwave Technologies manufactures microwave processing systems for evaporating water from several different industrial materials. For processes involving heating or drying, of which there are many, microwave energy increasingly acts as a substitute for more traditional ovens fired by oil or gas. Whether your industrial process involves bonding, curing, heating, drying, or cracking – FMT has a wide range of solutions. Our microwave systems serve as a more efficient approach to enhance materials, streamline throughput, and bring flexibility and control to your process.

Industrial Processing: Materials

For industrial processing applications, microwave treatment proves beneficial to several materials needing a heating or drying treatment. Typically, microwave systems are best fit for industrial products that are relatively thin sheet material, or loose granular products. However, we’ve seen emerging success with thicker products such as structural LVL lumber.

A short list of industrial materials, in which we’ve seen succes with microwave processing systems includes:

- Pulp

- Rope

- Paper

- Carpet

- Textiles

- Fossil Fuels

- Crumb Rubber

- Wood Products

- Engineered Foam

- Corrugated Paper

- Sludge Treatment

- Insulation Materials

- Bio-mass & Bio-solids

- Engineered Lumber (LVL)

Industrial Materials: Microwave Processes

Microwave systems are used for many stand-alone commercial heating and drying applications. Occasionally, best results may be achieved when applied to pre-heating materials before entering conventional dryers or heaters to raise the product moisture to its evaporative materials. Similarly, systems for industrial microwave processing may be used for post-drying materials after a conventional dryer or heater, to optimize the uniformity of its final moisture content.

Some typical processes our microwave systems achieve include:

- Drying

- Curing

- Heating

- Cracking

- Bonding

- Reacting

- Sterilizing

Ferrite Microwave Technologies has experience with designing and installing microwave technology (generators, systems, components) for several industrial materials processing applications. Our work spans several different industries, and we custom design solutions to meet the desired application requirements. We have the capacity and specialized design capability to integrate microwave devices and systems into existing processes and infrastructure, when applicable.

Our recent acquistion of IMS expanded our offering into the industrial materials sector further – with their single-mode systems, used extensively in several materials processing applications. Most notably, their products reach end users who process industrial materials such as foam, textiles, non-wovens, and beyond. The legacy systems by IMS include high-moisture heating and drying systems, as well as solutions for fluid, chemical, and liquid processing.

Product Examples

Lumber

Lumber preparation involves bonding layers of wood together and activating the adhesive withheat. Applications like this where spray-on adhesives are used, and then later activated, are excellent candidates for microwave treatment. Liquid adhesives activate very well when subjected to microwave power. We’ve manufactured specialized systems for lumber in the past, please contact us for details about that product.

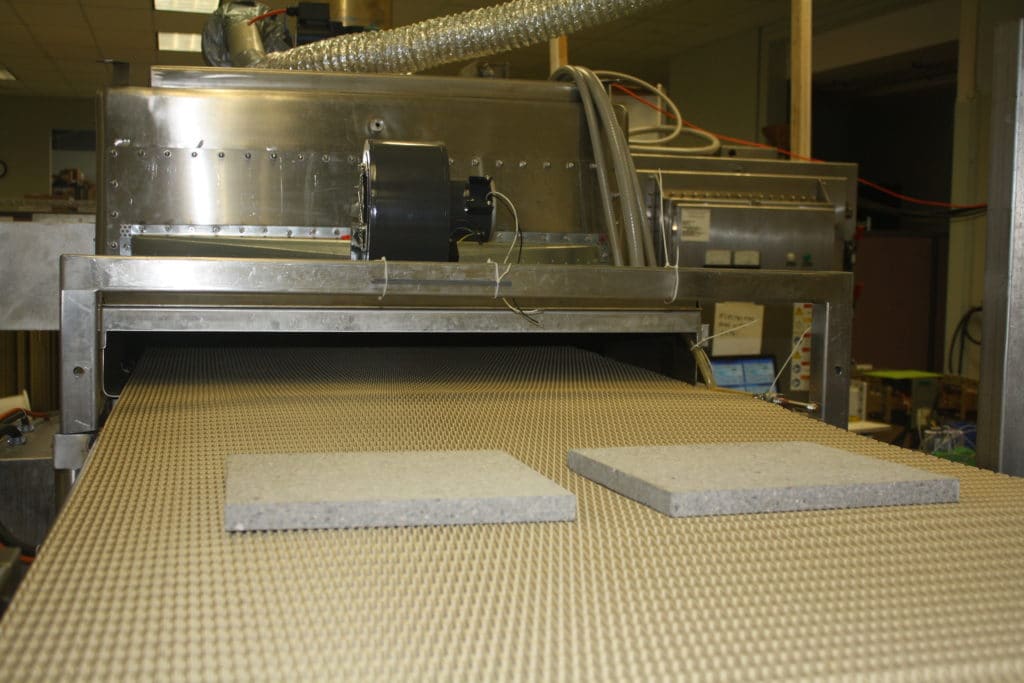

Foam

Foam is one of the natural candidates for microwave treatment. The manufacturing process involves extensive drying and the homogenous consistency and microwave transparency makes drying with microwaves very efficient.

Textiles

Textiles applications benefit from the excellent color drying and adhesive setting properties of microwave power. Also, as a process that involves drying as well, microwave treatment has an added benefit.

To learn more about FMT & IMS solutions for industrial materials microwave processing, please contact our support team. We’re ready to discuss your materials, current processes, and recommend a solution based on your exact needs.