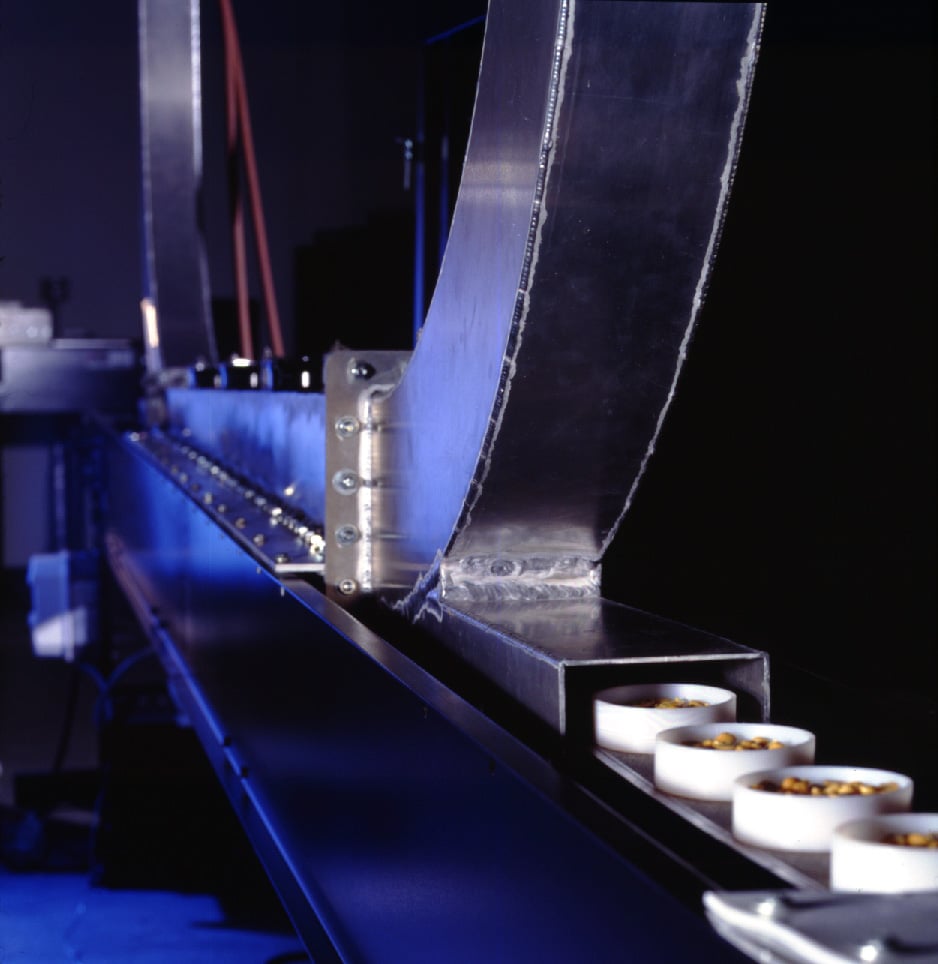

Ferrite Microwave Technologies In-Line High Moisture Microwave Heating & Drying System is an efficient solution to many product applications. When necessary to pre-heat moisture to evaporative temperature prior to entering a conventional dryer, post-dry materials to optimize final moisture uniformity, or purely for stand alone drying, this High Moisture (HM) Microwave System eliminates hot spots, and is an effective solution for several challenging heating and drying processes.

Patented Linear Applicator Technology

Our patented Linear Applicators eliminate hot spots by uniformly heating materials containing high moisture that easily absorb microwave energy. To maximize heating or drying efficiency, the patented single mode high moisture applicator ensures microwave energy field is uniformly distributed so that the target material achieves desired results. Our choke designs ensure that any electromagnetic emission is substantially less than that specified in federal regulations.

Applications & Benefits

A high moisture applicator consists of a cavity or oversized waveguide structure with variable attenuation capabilities. Its modular construction allows an electric field orientation, perpendicular to the material passing through the applicator on a microwave inert belt. The result is greater absorption of power by the material. A range of loose, granular to continuous, sheet material successfully heated or dried includes: grains, biomass, carpets, cereal, peanuts, pulses, seeds, and textiles.

The benefits to using an in-line microwave planar high moisture (HM) heating and drying system include:

- Increased production throughput, as high speak microwave heating reduces drying times

- Rapid power adjustments and on/off capabilities eliminate lengthy warm up and cool down times

- Microwave energy is increasingly absorbed in areas of high moisture content

- Yielding more uniform moisture gradients throughout the product being treated

- No Nitrogen Oxide (NOx) or Sulphur Oxide (SOx) emissions, typically associated with gas-fired dryers

High Moisture Heating & Drying Systems: Our Designs

We offer a series of modularized laboratory scale and commercial high moisture, in-line microwave heating and drying systems. These are available with control systems, as well as 915MHz or 2,450MHz microwave generators or transmitters. Modules can be combined in specific, customized configurations to match the required process specification, as well as fitting to the available production footprint. Please see tables below for designs, dimensions, and specifications.

STANDARD HM DESIGN OPTIONS

| Design Options | Laboratory Scale | Commercial Scale |

|---|---|---|

| Generator Frequency | 915 & 2,450MHz | 915MHz |

| Applicator Material | Aluminum (Stainless Steel available upon request) | Aluminum (Stainless Steel available upon request) |

| Product Height (max.) | 1″ (25.4 mm) | 2.5″ (63 mm) |

| Belt Material | Teflon coated fiberglass (Other materials available upon request) | Modular Polypropylene (Other materials available upon request) |

| Belt Speed | 0 – 100 feet per minute (0 – 30 meters per minute) | 0 – 134 feet per minute (0 – 40 meters per minute) |

| Belt Width | Variable to 4″ (0.10 meters) | 1′ – 8″ (0.51 m) |

| Electric Air Heater | Optional for drying application | Optional for drying application |

OPERATING PARAMETERS

| Single Module Process Specification | Laboratory Scale | Commercial Scale |

|---|---|---|

| Throughput (max.) | 132 – 396 lbs. per hour (60 – 180 kg. per hour) | 1,980 – 2,640 lbs. per hour (900 – 1,200 kg. per hour) |

| Moisture Removal (max.) | 11 – 33 lbs. per hour (5 – 15 kg. per hour) | 300 lbs. per hour (144 kg.) per hour |

| Temperature (max.) | Limited by product and belt material | Limited by product and belt material |

| Operating Pressure | Atmospheric at 14.7 psig (1.0 Barg) | Atmospheric at 14.7 psig (1.0 Barg) |

GENERATOR, CONTROL PANEL & APPLICATOR DIMENSIONS

| Dimension | Laboratory Scale | Commercial Scale |

|---|---|---|

| Length | 3’4″ (1.03 m) 1’7″ (0.48 m) 22’4″ (6.81 m) | 6’0″ (1.83 m) 2’8″ (0.81 m) (25’6″ 7.77 m) |

| Width | 1’9″ (0.54 m) 0’11” (0.27 m) 2’4″ (1.31 m) | 2’6″ (0.76 m) 0’9″ (0.23 m) 3’6″ (1.07 m) |

| Height | 5’9″ (0.76 m) 1’7″ (0.48 m) 3’10” (1.21 m) | 9’3″ (2.82 m) 4’0″ (1.22 m) 5’0″ (1.52 m) |

UTILITIES

| Factor | Laboratory Scale | Commercial |

|---|---|---|

| Power Output | 5 – 15 kW | 75 – 200 kW |

| Electricity (including Belt Drive Motor) | 7-20 kW | 90 – 240 kW |

| Magnetron Cooling Water* | 3 – 5.4 GPM (11 – 20 LPM) | 20 – 27 GPM (75 – 100 LPM) |

Actual process performance and specifications will depend on the throughput, properties, and heating range of the product.

*To eliminate the need for once through cooling water, we strongly recommend the use of a closed circuit chiller package for commercial applications.

To request additional information, or to speak with us about your project goals – please contact our support team. We’re always happy to learn about new applications, and recommend the best solution(s) possible, based on our experience.