Ferrite Microwave Technologies offers microwave heating systems for granular products, sheet materials, chemicals, liquids, foods, and more. Whether your application requires boost heating, preheating, or postheating, FMT specializes in solutions for the most challenging of heating processes. In addition, FMT has patented solutions for products with high-moisture content. Our microwave systems have proven results with products ranging from lumber, foam, plastics, and textiles – to microwave treatment of oil, coal, and bio-solids.

Heating Systems

Ferrite’s line of microwave heating systems includes designs for:

- 2450MHz and 915MHz

- Benchtop and Commercial

- Continuous/Tunnel, Ridged, In-Line, Cylindrical

- Preheating, Postheating, Heating, Boost Heating

- Customization, Modeling, & Design to meet specific requirements

- Ferrite Microwave Technologies & Industrial Microwave Systems

- Applications: Foam, Lumber, Nonwovens, Oil, Coal, Foods, Grains, Liquids, Chemicals, Textiles, Biomass, Corrugated Paper, Resins, and beyond

- Systems, Generators & Components: As a Microwave Techniques company, we are the global leader in microwave technology. We offer generators, loads, power combiners, circulators, isolators, waveguides & much more.

Microwave Heating Systems

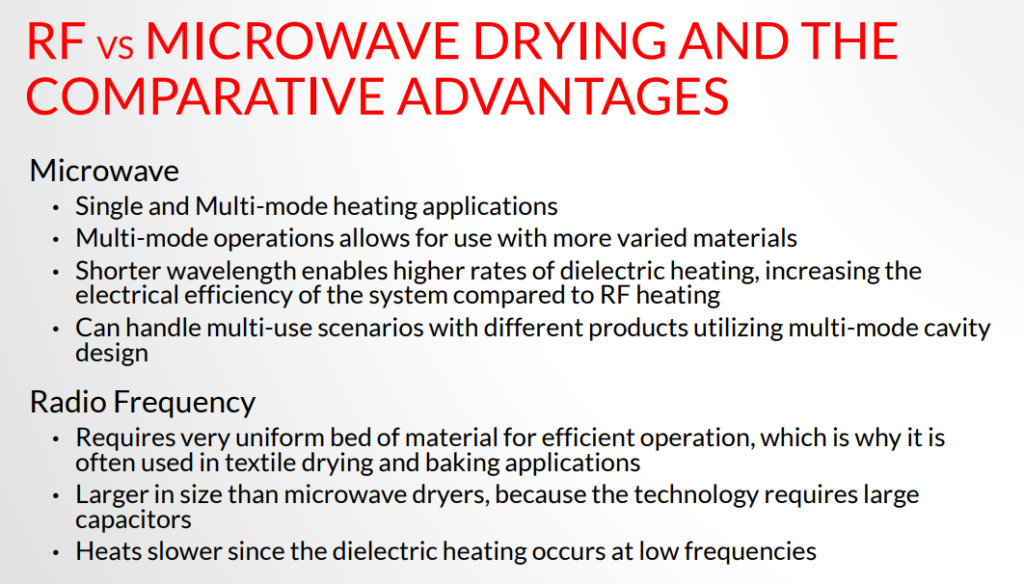

In microwave heating systems, there are single and multi-mode heating applications. Multi-mode operations allow for use with more varied materials. The shorter wavelength enables higher rates of dielectric heating, increasing the electrical efficiency, compared to RF heating. Similarly, it can handle multi-use scenarios with different products utilizing a multi-mode cavity design.

Food Heating

Microwave heating systems that utilize boost ovens significantly increase processing speeds and yields to an existing cooking line. Our boost ovens are used to quickly and uniformly increase product temperatures prior to the finish cook process. Thus, these systems reduce dwell times and increase throughput by as much as 30%, The process also has been shown to increase overall yields as moisture does not get driven off, in the effort to reach minimum cook temperatures. Not only does heating with microwave systems work faster, but it is usually more cost effective as well.

Chemicals Heating

We’ve worked with global petrochemical companies to help develop solutions that reduce production downtime due to frequent blockage of heater tubes. The company replaced a steam heated shell-and-tube exchanger with one of our chemical heating systems. As a result, we reduced the company’s product formulation cost as the high viscosity polymeric resin required less catalyst than previously required. Similar success stories in this marketplace include microwave-assisted extraction (MAE) with ionic liquids, biochemicals, and biopharmaceuticals.

Wood & Lumber

Microwave heating systems have varied uses in the production of various materials. For processes involving heating, of which there are many, microwave energy increasingly acts as a substitute for more traditional ovens fired by oil or gas. Our systems are widely used in structural LVL lumber processing. LVL lumber preparation involves bonding layers of wood together and activating the adhesive with heat. Applications like this, where spray-on adhesives are used, and then later activated, are excellent candidates for microwave heating systems.

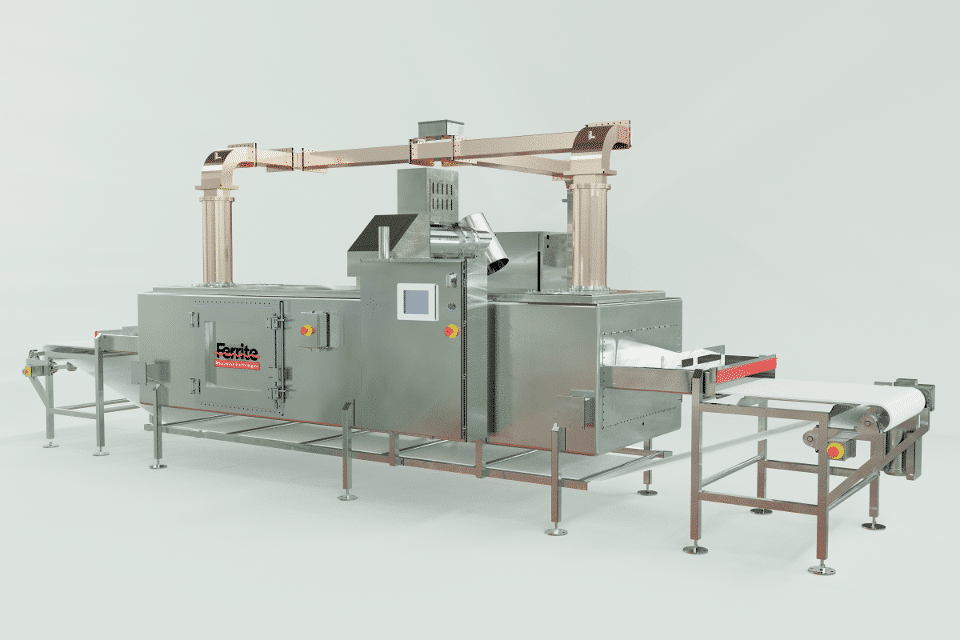

Microwave Heating: MIP9

Ferrite Microwave Technologies MIP9 heating system offers end users increased yield, throughput, and energy efficiency. It also allows its users flexibility through instantaneous controls. This unit offers boost heating capabilities for food applications, as well as heating capabilities for non-food applications. FMT customers utilize microwave heating systems to evaporate water from items like: snack foods, spices, biomass, foam, and coal.

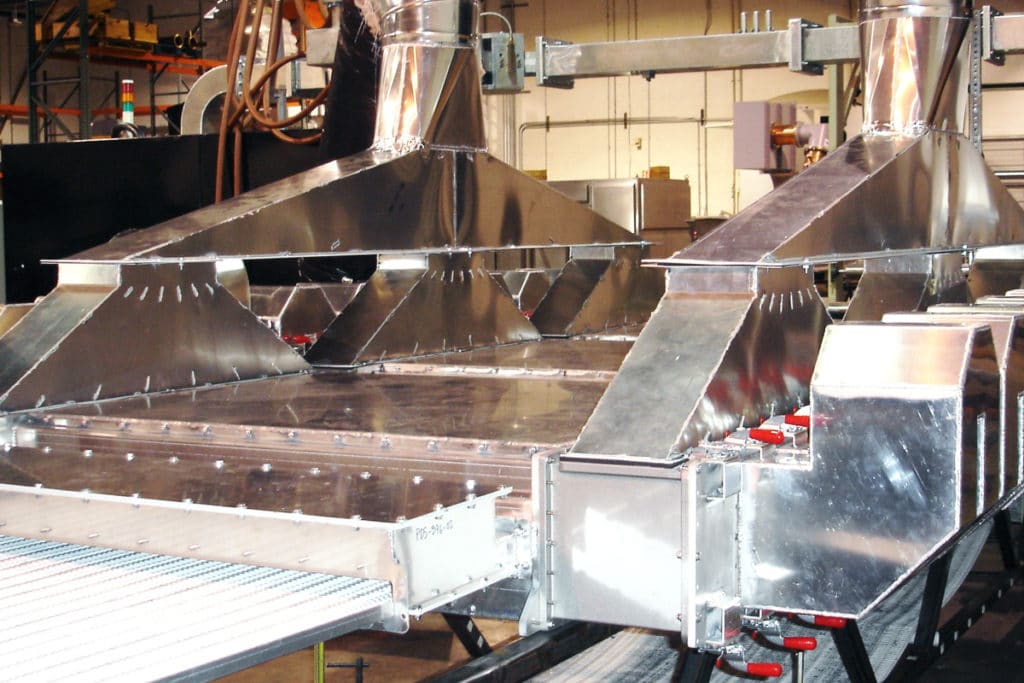

Planar Heating

Planar heating with microwave systems continuously heats and or dries a thin sheet or bed of product. Often, it is horizontally conveyed through a rectangular heating chamber or applicator on a specially selected microwave inert plastic modular belt. When combined with other thermal technologies, PHS can optimize final heater retrofits or new production lines. Optimum payback is usually obtained by utilizing a planar heater in a process application, either as a pre-heater or as a post heater, in combination with a traditional gas-fired re-circulating hot air dryer.

HM Heating

High moisture microwave heating systems are available for the textile, pet food, non-woven materials, foam, coal, biomass, and agricultural processing industries. These style systems are recommended as single or multiple units connected in parallel, series, or a combination of both. In some cases, it is possible to split the power from a single 100 kW generator into several input ports located along or across the applicators. This allows the conveyed material exposure to a lower power density which can improve the overall quality of a variety of heat sensitive products.

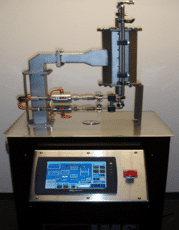

Liquids Heating

Ferrite Microwave Technologies specializes in rapid, continuous processing of high-value, heat and shear sensitive pumpable fluids. For thermal processing of chemical formulations, liquids, or fluids, we have the ability to test your product on a small-scale bench top microwave processing system similar to the 6 kW unit shown above. This system can use either a 1/2″ or 3/4″ ID product heating tube to minimize the hold up volume and amount of test fluid required. We’ve applied microwave technology to various chemical and industrial formulations.

RWG Microwave Heating System

Our patented RWG Applicator eliminates hot spots by uniformly heating thin materials of medium to low-moisture content. Typically, this system is for products that do not efficiently absorb energy by conventional conductive or convective heat transfer processes. Products successfully heated or dried in this system include: corrugated paper, crumb rubber, insulation materials, medical foam, non-woven materials, textiles, wood products, and more.

Microwave vs. Radio Frequency

You may be wondering: what is the difference between microwave and radio frequency heating? We’ve got you covered. Click here to find out the answer!