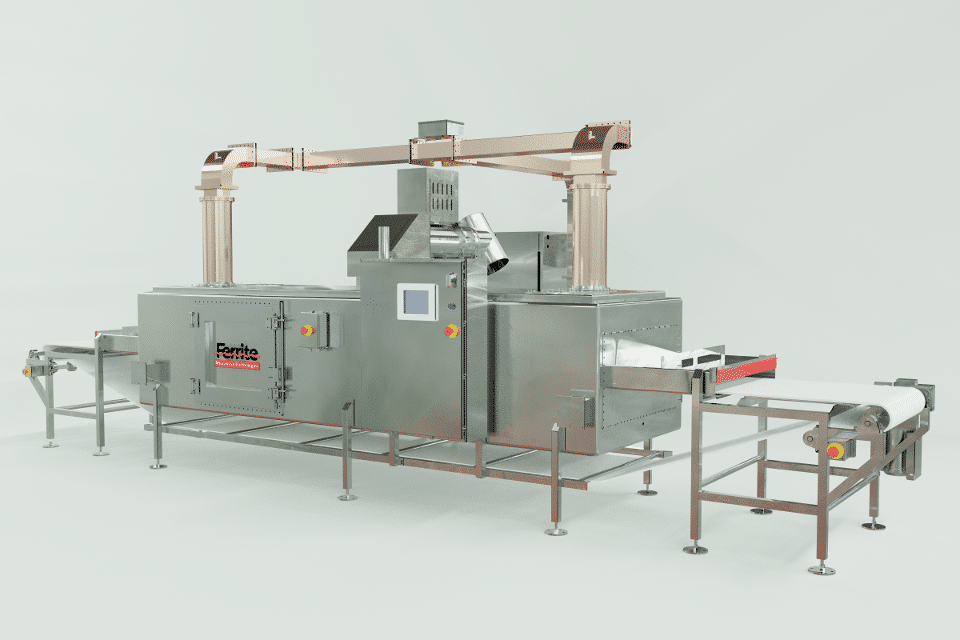

Ferrite Microwave Technologies heating, drying, and industrial processing system (MIP9) applies microwave energy to a variety of materials. This system is capable of improving a wide range of processes, with increases of throughput up to twenty-five percent. The MIP9 microwave heating, drying and processing system evaporates water and efficiently applies microwave energy to items such as: snack foods, spices, grains, biomass, industrial foam, textiles, coal, and much more.

Microwave Systems For Industrial Heating & Drying

FMT has a diverse portfolio of microwave heating and drying systems for industrial processing of foodstuffs and non-food materials. The MIP9 is best suited for products that need a raise in temperature, or products needing water removed.

Typically located prior to a conventional line, the processing oven increases both throughput and yield by raising the temperature of the entire product. Throughput increases as a natural result of the “boost.”

The resulting increases in product yields are even more impressive. By raising the core temperature of the product, there is less reliance of the conductive heat transfer to achieve minimum temperatures. This, in turn, results in less moisture driven from the outer portion of the product. Thus, leading to a higher final yield.

About the MIP9 Microwave Processing System

The MIP9 heating, drying, and microwave processing system consists of one fifteen (15) foot long heavy duty stainless steel multi-mode cavity. Each cavity has two (2) access doors for easy cleaning, along with a sloped bottom pan leading to a waste collection pipe system. Each cavity comes equipped with two (2) high-power microwave rotary feeds, one top and one bottom, to enhance energy distribution. Suppression tunnels on the input and output prevent microwave leakage into the surrounding work area. The cavity features half and full product detection and arc sensing.

Microwave Drying vs. Heating

The use of microwave energy for drying and heating applications is increasing. Although the processes of microwave drying vs. heating differ in terms of product, speed, throughput, and end goals – the processes are very similar. Essentially, whether you are heating or drying with microwaves – you’re using microwave treatment to prepare products.

If the goal is to evaporate water from a material, like engineered lumber, or boost the temperature of a food product – the MIP9 system is capable. FMT customers are utilizing the energy efficiency of microwave treatment to evaporate water from items ranging from agricultural grain products to building materials. Similarly, microwave heating, drying and processing systems are used for a number of bonding applications for several industrial materials.

Microwave Drying, Heating & Processing: FAQs

Below are some frequently asked questions about Ferrite Microwave Technologies’ MIP9 Microwave Heating, Drying & Processing System. In the event you have additional questions, our team is always here to help.

How is product transported in the MIP9?

A 36-inch wide positive drive, articulated belt of microwave transparent material. The belt transports the product through the oven.

What size products fit into the system?

Standard systems accommodate beds of material 34″ x 3″ (86 cm. x 8 cm.). However, other tunnel sizes are also available.

How safe is it?

Our goal is to provide the safest operating environment available. All FMT products meet or exceed all applicable safety standards issued by OSHA or Health & Human Services. Safety exposure limits of 5mW/cm² measured 5 cm away from the equipment are twice as stringent as OSHA’s voluntary standard. In addition, fittings are provided upon request to interface with an optional, customer-supplied fire suppression system. Light and temperature sensors in the oven send signals to trigger the system.

To learn more about FMT’s microwave heating, drying, and processing systems – please contact our support team.