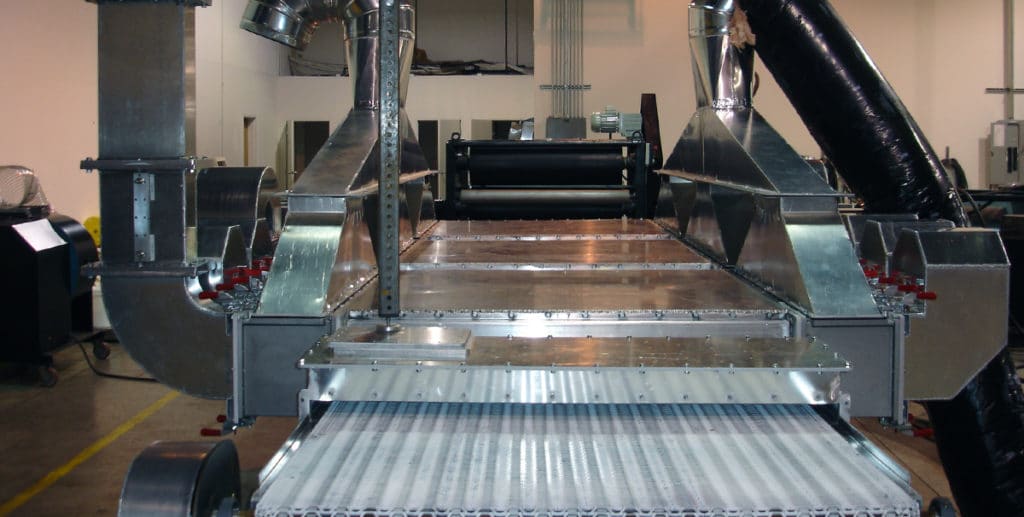

Ridged Waveguide (RWG) Microwave Systems for heating and drying consist of specially designed waveguides arranged in a serpentine pattern. The RWG system eliminates hot spots by uniformly heating thin materials. Typically, products best fit for ridged waveguide systems are medium to low moisture content materials unable to efficiently absorb energy by conventional conductive or convective heat transfer processes. It is used to post-dry materials and for standalone drying.

Applications for Ridged Waveguide (RWG) Systems

The RWG microwave system is suitable for a wide range of applications. Its modular design allows an electric field orientation that is parallel to the material passing either on a microwave inert belt through the applicator, or directly as a substrate without a belt. The result is greater absorption of power by the material.

Typically, the product applications which prove most successful in the ridged waveguide applicator are loose granular products and continuous sheet materials. A range of products that has successfully heated or dried include: corrugated paper, crumb rubber, insulation materials, medical foams, nonwoven materials, textiles, and wood products.

Benefits of Using RWG Microwave Systems

The benefits of utilizing a ridged waveguide microwave system include:

- Suitable for either vertical or horizontal applications

- Modular design and construction allows for compact footprint

- Microwave energy distribution reduces risk of over-drying or scorching the product surface

- Lower energy consumption than conventional dryers with products containing less than 15% moisture

- Increases production and throughput with high-speed microwave heating, reducing overall drying times

Our Patented Designs

To maximize heating or drying efficiency, the patented single mode Ridged Waveguide Applicator ensures microwave energy field is uniformly distributed so that the target material achieves desired results. We offer RWG systems in Laboratory (2,450MHz) and Commercial (915MHz) Scale. The following specifications apply:

OPERATING PARAMETERS PER MODULE

| Single Module Process Specification | Laboratory Scale | Commercial Scale |

|---|---|---|

| Max. Throughput | 132 to 396 lbs./hr. (60 to 180 kg./hr.) | 1,980 to 2,640 lbs./hr. (900 to 1,200 kg./hr.) |

| Max. Moisture Removal | 11 to 33 lbs./hr. (5 to 15 kg./hr.) | 300 lbs./hr. (144 kg./hr.) |

| Max. Temperature | Limited by product & belt material | Limited by product & belt material |

| Operating Pressure | Atmospheric @ 14.7 PSIG (1.0 Barg) | Atmospheric @ 14.7 PSIG (1.0 Barg) |

DESIGN OPTIONS

| Component Specification | Laboratory Scale | Commercial Scale |

|---|---|---|

| Generator Frequency | 2,450MHz | 915MHz |

| Applicator Material | Aluminum (SS available upon request) | Aluminum (SS available upon request) |

| Max. Product Height | 1 inch (25.4 mm) | 2 inches (51 mm) |

| Belt Material | Teflon coated fiberglass (other materials available upon request) | Teflon coated fiberglass (other materials available upon request) |

| Belt Speed (not limited if using substrate only) | 0 to 100 ft./min. (0 to 30 m/min.) | 0 to 134 ft./min. (0 to 40 m/min.) |

| Belt Width | Variable to 18 inches (0.46 m) | Variable to meet customer specification |

| Electric Air Heater | Optional for drying application | Optional for drying application |

GENERATOR, CONTROL PANEL & APPLICATOR DIMENSIONS

| Dimension | Laboratory Scale | Commercial Scale |

|---|---|---|

| Length | 3’4″ (1.03 m) 1’7″ (0.48 m) 8’0″ (2.42 m) | 6’0″ (1.83 m) 2’8″ (0.81 m) Depends on application |

| Width | 1’9″ (0.54 m) 0’11” (0.27 m) 4’4″ (1.31 m) | 2’6″ (0.76 m) 0’9″ (0.23 m) Depends on application |

| Height | 5’9″ (1.76 m) 1’7″ (0.48 m) 4’0″ (1.21 m) | 9’3″ (2.82 m) 4’0″ (1.22 m) Depends on application |

UTILITIES

| Factor | Laboratory Scale | Commercial Scale |

|---|---|---|

| Power Output | 5 to 15 kW | 75 to 200 kW |

| Electricity (including belt drive motor) | 7 to 20 kW | 90 to 240 kW |

| Magnetron Cooling Water* | 3 to 5.4 GPM (11 to 20 LPM) | 20 to 27 GPM (75 to 100 LPM) |

Actual process performance and specifications always depend on throughput, properties, and heating range of a product.

To learn more about FMT’s In-Line Ridged Waveguide Microwave Heating & Drying System, please contact our support team. We look forward to learning about your current process, project goals, product specifications, and more!