Ferrite Microwave Technologies Planar Heating Microwave Systems (PHS) allow processors to improve their cost effectiveness and quality. Whether used to post-dry materials after a conventional dryer to optimize final moisture uniformity, or purely for stand-alone drying, planar heating microwave systems offer an efficient solution to many challenging heating and drying processes. PHS provide unique advantages over conventional dryers or heating systems.

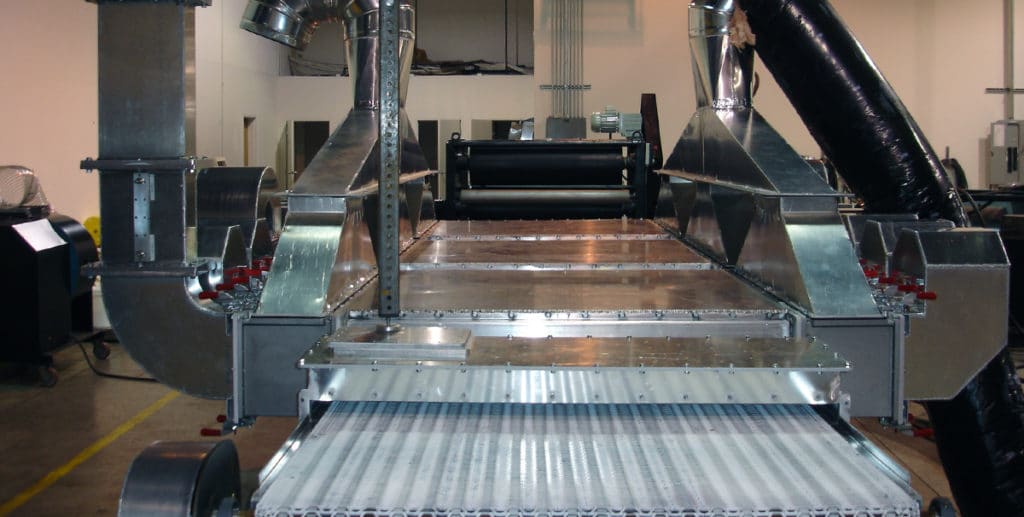

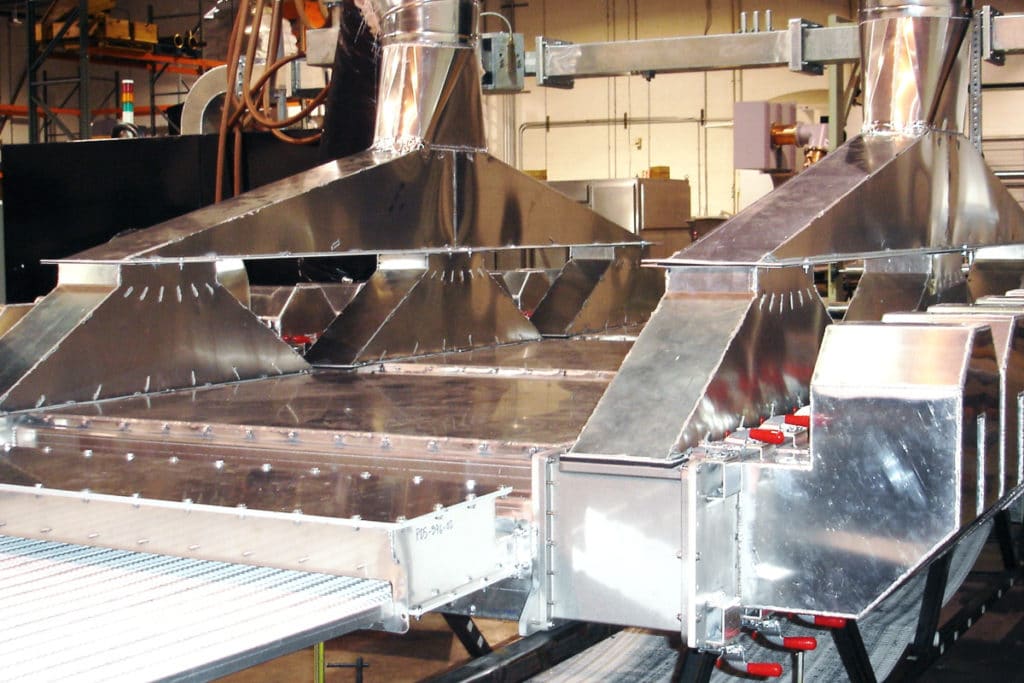

Planar Heating Systems: Our Designs

We offer a series of standard and modularized planar heating systems, suitable for laboratory scale and commercial environments. These modules can be combined in specific customized configurations to match the required process specification. In addition, our team can assist with fitting a system into the available production footprint, if necessary.

- Lab Scale or Commercial Size

- In-Line Planar High Moisture (HM)

- Inert belt or substrate (without belt)

- Designs for 2,450MHz and 915MHz

- In-Line Planar Ridged Waveguide (RWG)

- Development of non-standard applicators for custom applications

Product Applications

Although our Planar Heating Systems can be used for many product and process applications, we typically see our customers share one of two goals. Most users are looking to either (1) preheat a product to an evaporative temperature, or (2) remove water from products with relatively low overall moisture content.

The typical applications for planar heating systems are:

- Coal

- Rope

- Foam

- Cereals

- Textiles

- Peanuts

- Biomass

- Crumb Rubber

- Pulses & Seeds

- Wood Products

- Corrugated Paper

- Nonwoven Fabrics

- Biodiesel Products

- Pet Foods & Treats

- Insulation Materials

- Agricultural Materials

Benefits of Heating with Planar Microwave Systems

Planar Heating Systems (PHS) allow processors to improve their product cost effectiveness and quality, increase production volumes, reduce equipment footprint or floor space, and improve the manufacturing environment, as the PHS generates no NOx or SOx emissions.

The volumetric heating that results from the agitation of the polar molecules in the product, results in rapid, uniform heating and/or drying of the product in a fraction of the time required by a conventional dryer. These benefits are achieved without the high installation and maintenance costs, downtime, and pollution often associated with conventional dryers.

Its specific benefits and economic advantages are best achieved when applied to pre-heating materials before entering a conventional dryer to raise the product moisture to its evaporative temperature, or post drying materials after a conventional dryer to optimize the uniformity of its final moisture content.

Since we offer three different types of planar applicators, it may provide a better solution than a one-size fits-all multimode microwave planar design. Overall, our PHS offer several advantages over conventional dryers.

To discuss your application, please contact our support team. Our team looks forward to learning about your current process, project goals, and finding a planar heating microwave system solution to best fit your exact requirements.