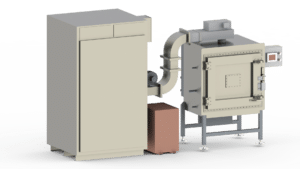

Ferrite Microwave Technologies mini batch microwave tempering oven (MIP4) is for food processing applications that need to temper on demand. The MIP4 is best for low to mid volume food service operations that need to temper moderate quantities of food in a hurry with limited space. It is ideal for meat, chicken, fish, fruit, and bakery products. This mini batch microwave tempering oven can temper up to 1,500 pounds (680 kg) of raw, frozen product per hour.

About the MIP4 Microwave Tempering Oven

The MIP4 Mini Batch Microwave Tempering Oven automatically raises the average temperature of frozen product between 22 and 29 degrees Fahrenheit (-2 degrees Celsius) at the touch of a button. As a complete microwave system, the MIP4 consists of a compact microwave oven, in addition to a 35 kilowatt microwave generator. The unit ships with a full 75 kW generator, that is control limited down to 35 kW. Precise computer control of processing variable enables predictable temperature increase (tempering) and final target temperature attainment. Typically, this mini batch microwave tempering oven can temper a 55 pound (25 kilogram) box of beef in 65 seconds. The MIP4 provides uniform heating and enables tempering from low starting temperatures with consistency using FMT’s unique rotary table.

Advanced Microwave Technology

Decades of diligent research and development, as well as real-life tempering trials for customers, in widely varied areas of the food processing industry, haven driven the industry-leading technology contained in the MIP4 system.

The MIP4 has a 3-foot by 4-foot (0.9 meter by 1.3 meter) mini batch tempering microwave oven. It also comes complete with its own microwave generator. The unit operates at 915MHz, and produces +/- 120,000 BTUs per hour for superior food processing performance.

The generator is controlled by a Programmable Logic Controller (PLC) processor. The PLC operates the control software for the generator. The PLC processor enables constant power operation at preset power levels. It also provides a digital display of status information. This includes actual vs. set point power, and fault diagnosis.

Benefits of Using a Mini Batch Tempering Microwave Oven

Mini batch microwave tempering ovens offer speed, control, convenience, and cost savings. In addition, food processors can expect the following benefits from utilizing a system like the MIP4:

- Savings: on time, space and labor cost

- Safety: less handling of product, less risk for injury

- Sanitation: improvements to your facility and product cleanliness

- Predictability: enables a more predictable final temperature attainment

- Quality: higher flavor retainment, more protein compounds for consumers

- Flexibility: adds process flexibility with tempering on demand for better service

- Compliance: simplifies the users compliance with government sanitation regulations and guidelines

Mini Batch Microwave Tempering Oven: FAQs

To help you better understand our products, we’ve compiled a short list of frequently asked questions regarding the MIP4 Mini Batch Microwave Tempering Oven.

What are typical applications of the mini batch tempering oven?

Typical food processing applications include around-the-clock tempering of a wide variety of products. Often, we see ovens such as the MIP4 best suited for low to mid volume, continuous flow applications, such as a cruise ship galley.

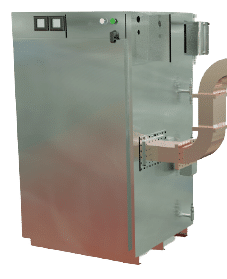

Is it washdown safe?

Yes. The MIP4 tempering oven is stainless steel and is washable. The generator cabinet is a sealed enclosure.

What are some of its safety features?

Interlocking access doors on the generators meet all applicable government (OSHA and Health & Human Services) safety standards, and provide the safest operating environment available. Fittings can be provided to the oven to interface with an optional, customer-supplied fire suppression system. Customer supplied light and temperature sensors may be used in the oven to send signals to trigger the system.

Is a warranty available?

The MIP4 mini batch microwave tempering oven is warrantied for a period of one year. However, FMT offers both in- and out-of-warranty service support, handled by our certified field technicians.

About the Generator: Details & Specifications

FMT generators are water cooled through a heat exchanger using city or local water supply. The MIP4 system includes a one-inch inflow and outflow pipe. Flow rates depend on the temperature of water entering the heat exchanger (optional temperature control valve is recommended).

All controls for typical generator operation are found on the front of the enclosure. This ensures consistent, uniform, and efficient tempering.

The MIP4 generator is electrically isolated from the process oven. This is on account of an integral microwave circulator that helps provide long magnetron tube life. Because of the efficiency of FMT’s waveguide power transmission, it is possible to install the generator in a remote location.

Electrical Specifications (per generator) United States:

INPUT LOAD

| 480 volts | 440 volts |

| 3 phase | 3 phase |

| 50 / 60 cycles | 50 / 60 cycles |

| 72 amps | 80 amps |

| 60 KVA | 60 KVA |

MICROWAVE OUTPUT

| 75 kW |

| 915 MHz |

| Magnetron microwave power source |

To learn more about Ferrite Microwave Technologies MIP4 Mini Batch Tempering Oven, please contact our support team.