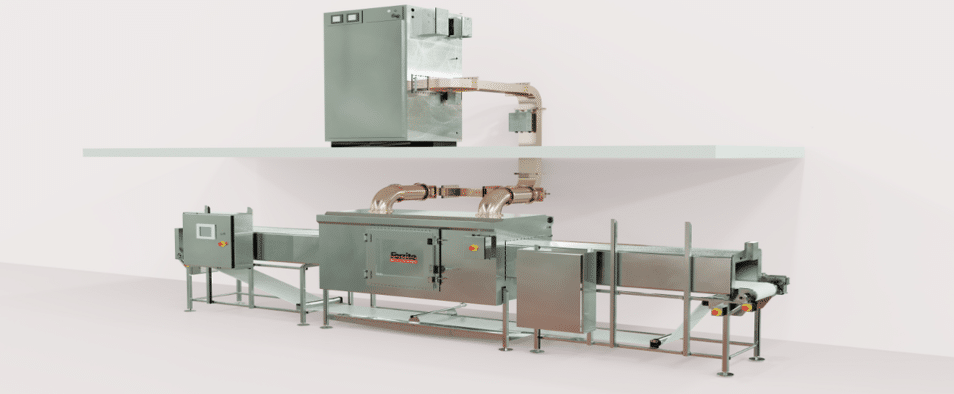

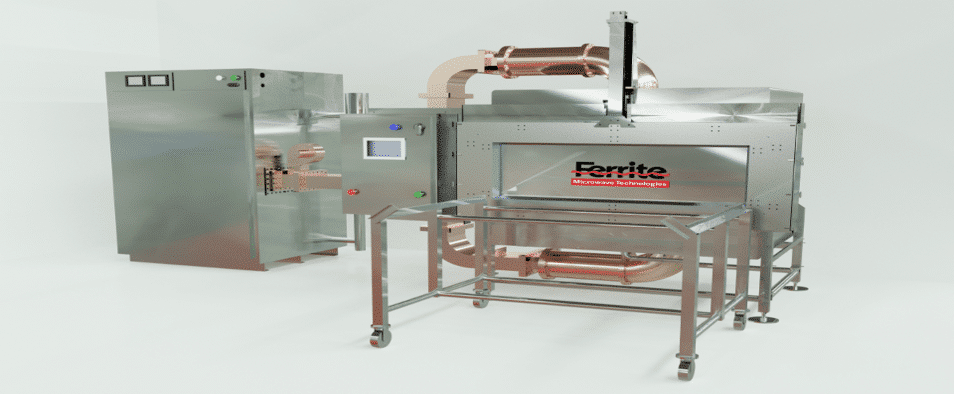

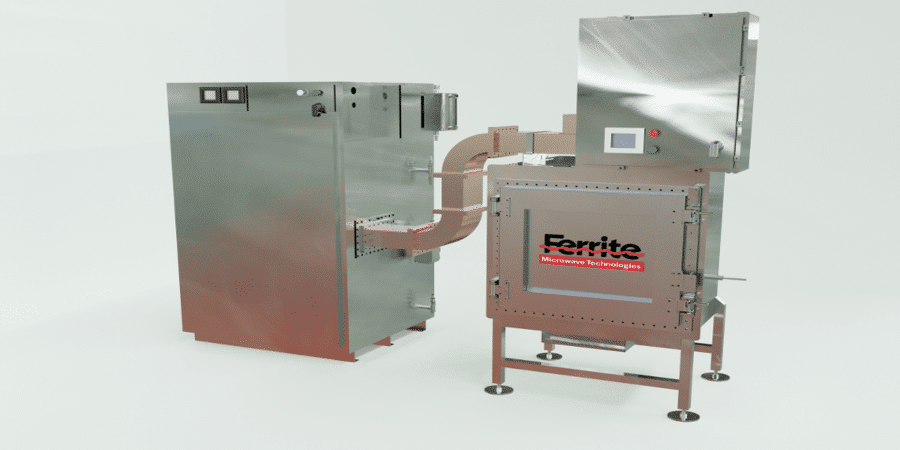

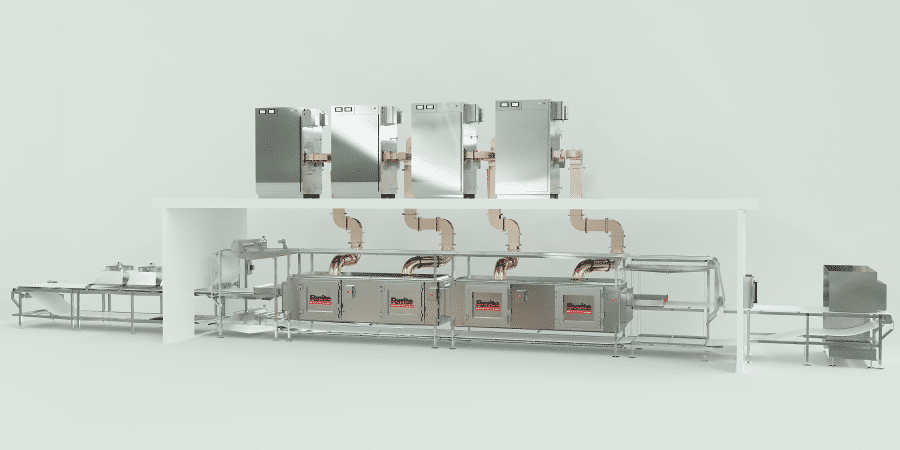

Ferrite Microwave Technologies food processing microwave systems are used to dry, boost-heat, temper, or fully cook a variety of foods. Microwave energy has been utilized by the food processing sector since the 1970s for cooking and uniform tempering of deep frozen products. Recent advances in technology has opened up new applications for processing foods. All FMT food processing systems are FSMA and FDA compliant and constructed of food-grade materials. We can also add microwave power to existing equipment, like an industrial blender.

Food Processing: Overview

An overview of our microwave systems for the food processing industry:

- Brands: Ferrite Microwave Technologies & Industrial Microwave Systems

- Design Types: Batch Ovens, Continuous Tunnels, Indexing Processors, Planar Heating, Cylindrical, In-Line, Tubular, Lab-Scale, Benchtop

- System Processes: Tempering, Thawing, Defrosting, Boost-Heating, Cooking, Sterilization, Gelation, Pasteurization, Thermal Processing

- Products & Applications: Meat, Beef, Chicken, Fish, Pork, Bacon, Sausage, Fruit, Vegetables, Spices, Snack Foods, Seeds, Pulses, Grains, Cheeses, Soy Milk, Pureés, Surimi, Peanuts, Cereals, Sauces, Bread, Slurries, and beyond…

Tempering

Microwave systems are widely used for tempering deep frozen beef, pork, poultry and fish. Replacing conventional processes like tempering rooms, our MIP12 continuous tempering system is capable of accomplishing the task in a matter of minutes. Our blog post on the benefits of microwave tempering is a must read for anyone considering alternatives to tempering rooms or conventional ovens. Besides the obvious time savings, major benefits include higher protein yield, less mess and energy efficiency.

Food Processing: Drying

Food products like spices, snacks and other bulk products often need to be finish dried once they are processed. Processing food with microwave drying systems provides the flexibility to adjust throughput without costly heating and cooling cycles necessary for conventional drying.

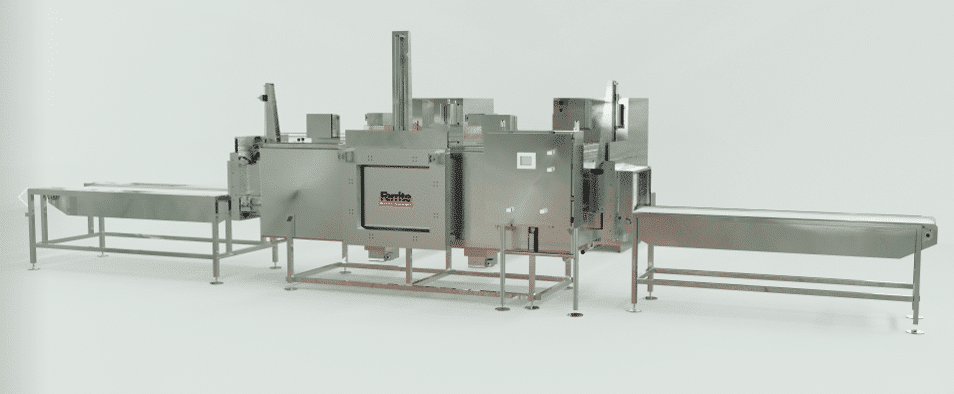

Boost Heating

Microwave boost heating ovens significantly increase processing speeds and yields to an existing conventional cooking line. Boost Ovens are used to quickly and uniformly increase product temperatures prior to the finish cook process, thereby reducing dwell times and increasing throughput by as much as 30%. The process also has been shown to increase overall yields as moisture does not get driven off in the effort to reach minimum cook temperatures.

Food Processing: Cooking

The majority of the food processing microwave cooking market is pre-cooked bacon. That’s because the vast majority of the pre-cooked bacon in the world in processed with microwave systems like the MIP11. Learn why our Bacon Cooking lines are the preferred choice of some of the largest bacon producers in the world.