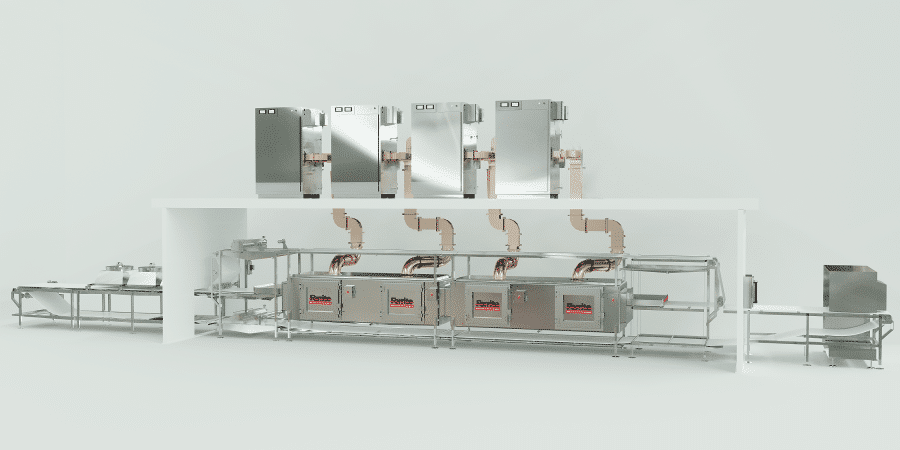

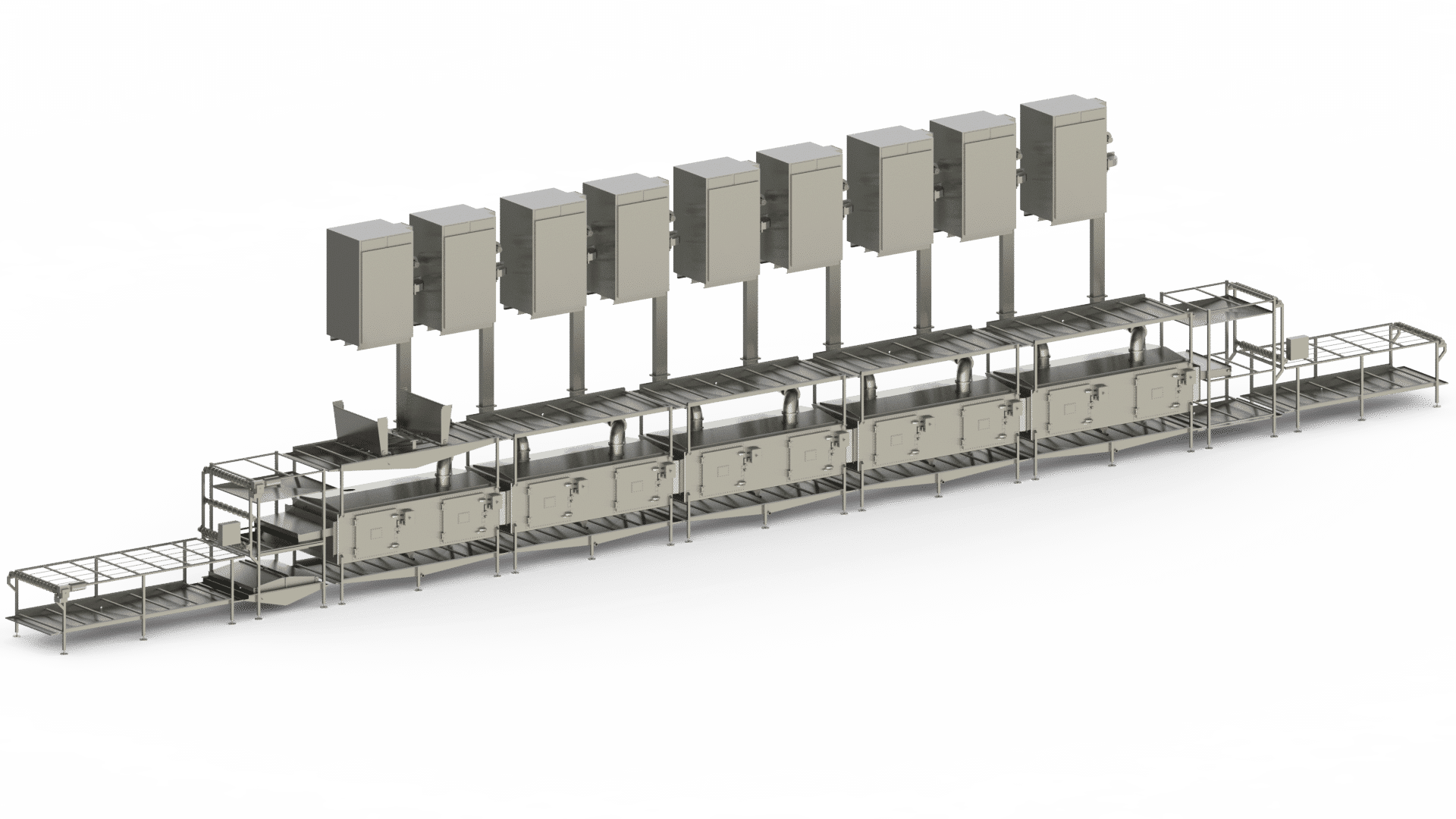

Ferrite Microwave Technologies Continuous Microwave Cooking Oven System (MIP11) provides efficient, uniform cooking at various speeds and settings. With the MIP11, you control the speed and power at which your product is prepared.

Most typically installed at facilities processing pre-cooked bacon, this continuous microwave oven provides users the flexibility to process thousands of product per hour, depending on the product and process variables. The MIP11 meets the requirements of a broad range of product applications. Trust in the essential ingredients of smooth, efficient, and continuous microwave cooking provided by the MIP11 for meeting today’s production demands.

Uniform, Efficient, & Continuous Microwave Cooking

The MIP11 provides efficient, uniform, and continuous microwave cooking to provide consistent and proven results. Products up to 3 inches (7.62 centimeters) thick can be uniformly heated by FMT’s microwave feed technology. FMT’s feeds efficiently and evenly apply microwave energy to products inside the process oven.

- All MIP11 system layouts can be modified and designed to accommodate specific customer requirements

- Multiple 4-foot wide by 12-foot long (1.3 meters by 3.7 meters) cooking cavities

- Overall length options from 24.5 feet (7.5 meters) to 63.5 feet (19.4 meters)

- Overall length of basic single cavity system is 24.5 feet (7.5 meters)

- System includes all controls, as well as input and output conveyors

- Product opening of 3 inches (76 mm) by 36 inches (864 mm) wide

- Power options: 75, 150, 225, 300, 375, 450, 525, or 600 kW

- 3-foot wide (0.9 meter) continuous conveyor system

- One or two microwave generators per cavity

Continuous Microwave Cooking Oven: Design Options

Ferrite Microwave Technologies offers several options for the Continuous Microwave Cooking Oven (MIP11), including:

- A complete 2-inch (50 mm) thick, insulated cavity for heat containment and energy efficiency

- FMT Belt Cleaner (FBC) system, employing high pressure water to remove product residue and grease from belt

- FMT Air Dry system, high pressure blow-off to remove excess grease and water before packaging

- The air dry system may also be utilized to remove grease or water from conveyor belt after washing with FBC

| Oven Model Number | Power | Length in feet (meters) |

|---|---|---|

| MIP11-1 | 75 / 100 kW | 24.5 (7.5) |

| MIP11-2 | 225 / 300 kW | 37.5 (11.5) |

| MIP11-3 | 375 / 450 kW | 50.5 (15.4) |

| MIP11-4 | 525 / 600 kW | 63.5 (19.4) |

Length includes suppression assembly, not extension conveyors on either end

Benefits of Cooking with Continuous Microwave Ovens

The benefits of cooking with continuous ovens mostly center around speed, production, flexibility, efficiency, and cleanliness. When you utilize a continuous oven, you control the speed and power at which your product is prepared. Here are some other benefits you can expect:

- Support: remote system monitoring and tracking via Ferrite Information Management System (FIMS)

- Accessibility: troubleshooting by certified service technicians via modem access to PLC controls

- Control: automatic system monitoring and precise control with product sensors

- Expansion: easily expand the system at any time to increase production

- Flexibility: change the power, speed, and other processing variables

- Reliability: industry-proven Allen-Bradley controls

- Simplicity: user-friendly FMT system software

Continuous Cooking Ovens: FAQs

To help you better understand our continuous cooking ovens, we’ve compiled a short list of frequently asked questions and answers. The answers below apply specifically to our MIP11 system.

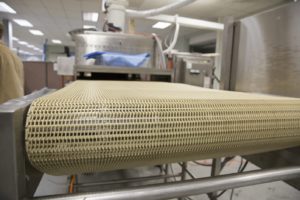

How is the product processed and transported through the oven?

A standard 3-foot wide (0.9 meter) positive drive, articulated belt of microwave transparent material transports the food product through the processing oven. Although this is simply standard, other belt widths are also available.

How much product can the MIP11 process in one hour?

Depending on the specific product and its given processing variables, the amount of product cooked per hour may vary. However, a general estimate is up to 1,800 lbs. (817 kg.) of product per hour.

What are food products are ideally suited for cooking in a continuous microwave oven?

Although this system is predominately used for bacon processing, we’ve seen end users cook various meat, chicken, fish, and other food products.

What is unique about FMT’s designs?

We have designed several polarized feeds and patented technology to increase cooking uniformity, mode mixing, and minimizing footprint. FMT systems and generators are designed to minimize cavity match losses. Our SPC antenna, coupled with our polarized waveguide launchers, set up field uniformity without the associated loss.

MIP11: Video Demonstration

The video below is a short demonstration of bacon processing in our MIP11 Continuous Microwave Cooking Oven.

To learn more about Ferrite Microwave Technologies complete line of continuous microwave cooking ovens, please contact our support team.