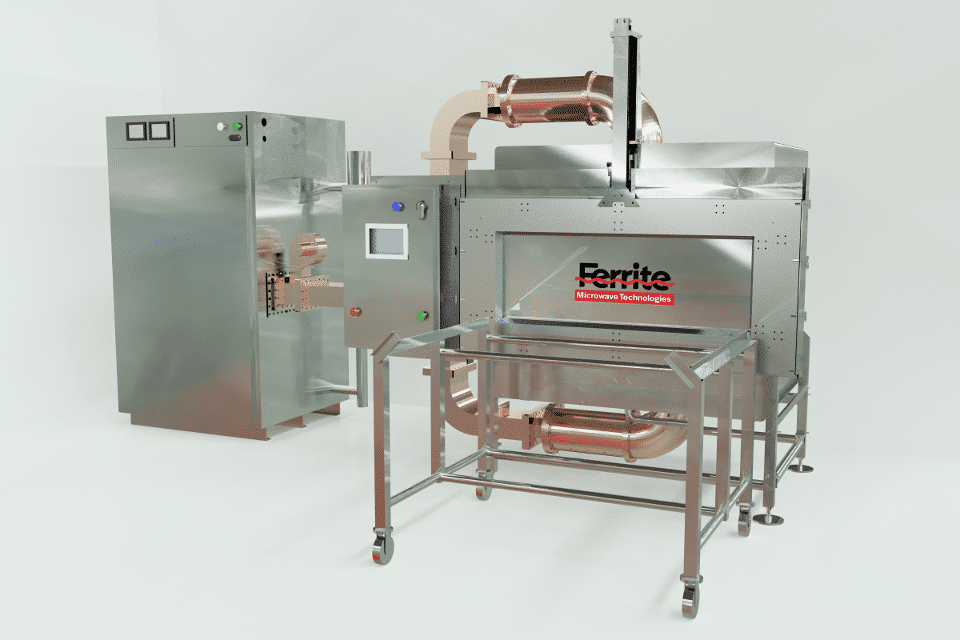

Ferrite Microwave Technologies Batch Processing Microwave Oven (MIP10) is a precise, easy-to-use tempering oven for frozen food processing. If your application involves a myriad of different products, or relatively low throughput, a batch processing microwave oven system will suit your needs better than a continuous tunnel, or belt-driven system. With the MIP10, there is no minimum loading requirement, and the footprint is much smaller than a tunnel-style system.

A Complete Batch Processing Microwave Oven System

The basic system consists of a 50-inch by 42-inch (1.3 meter by 1.1 meter) microwave oven, one FMT GET 2024 75 kilowatt microwave generator and a loading table on convenient rollers. The oven size permits a uniform loading procedure for the simultaneous processing of one 10-inch high (254 millimeter) tier of containers placed on the 40-inch by 48-inch (1.02 meter by 1.22 meter) loading table. Typically, this microwave oven tempers a load of about 300 pounds (136 kg) in four minutes. During a single shift, it automatically and precisely raises the temperature of up to 3,000 pounds (1360 kg) of frozen product to 28 degrees Fahrenheit (-2 degrees Celsius).

The Benefits of Utilizing Batch Ovens

One benefit of utilizing a batch processing microwave oven is that you can set up precise batch tempering of frozen meat, fish, poultry, fruit or bakery products in just minutes. Batch ovens are ideally suited for portion-control plants, ground beef and poultry operations, sausage kitchens, bakeries and frozen prepared-food manufacturing.

Batch ovens provide uniform heating for consistent, efficient tempering of product at very low starting temperatures.

Another benefit is that batch processing ovens improve your product quality. Batch tempering food with these style ovens also retain protein and flavor compounds for tastier, fresher products.

Lastly, with a batch processing microwave unit installed, tempering rooms are eliminated. The resulting drips, or liquid runs, common in the food processing industry, are no longer a worry.

Overall, batch processing microwave ovens keep your facility clean, and take up less space along the way.

Advanced Technology & Ongoing Support

As a leader in industrial microwave batch oven development, FMT offers the widest variety of batch cooking and tempering ovens on the market. The MIP10 system is covered by a full one-year warranty. Both in- and out-of-warranty service support is provided by FMT Certified field technicians. Our field techs also offer remote troubleshooting, as well as customer support for all questions, proposals, or future plans for the MIP10 in your facility. Precise computer control of processing time enables predictable temperature increases (tempering) and target final product temperature attainment.

Watch Video: MIP10 Demonstration

Batch Processing Microwave Ovens: FAQs

To help you better understand our Batch Processing Microwave Oven System (MIP10), we’ve provided answers together to a short list of some frequently asked questions. As always, if you find you have other questions, or you wish to learn more about the MIP10, please contact our customer support team to speak with a microwave expert at FMT.

How is the product transported?

A 5-foot by 5-foot (1.5 meter by 1.5 meter) heavy duty plastic pallet, conveniently mounted on rollers. Please view the video above for a short demonstration.

Is the batch oven washable?

Yes. The batch processing microwave oven is washable. The MIP10 batch oven and microwave generator are both manufactured entirely from stainless steel.

Does it meet safety standards?

Yes. Safety remains our top priority in our system designs. The generators offer interlocking access doors. These meet all applicable safety standards. The MIP10 provides a safe and stable operating environment.

How long does it take to temper product in a batch oven?

We’re glad you asked! We’ve compiled data of products commonly tempered in our MIP10 Batch Oven. See the table below for typical time required to temper 300 pound loads in 75 kW unit from Zero degrees (-18 degrees Celsius) as starting temperature.

| Product | End Temperature | Time (minutes) |

|---|---|---|

| Lean Beef (85%) | 26° F | 4 |

| Lean Beef (50%) | 22° F | 2 |

| Pork | 22° F | 2 |

| Poultry | 27° F | 5 |

| Cod Blocks | 22° F | 3 |

| Cored Apples | 21° F | 3 |

To learn more about Ferrite Microwave Technologies range of batch processing microwave oven systems, or to speak with an expert about your application – please contact our dedicated customer support team. As the global leader in high-power microwave systems, we look forward to learning about your current process, product(s), and project goals!