Ferrite Microwave Technologies batch microwave oven systems are better suited for low- to mid-volume tempering and processing applications. There is no minimum loading requirement and the footprint is smaller than comparable continuous-style systems. If your application requires a myriad of different products, or relatively low throughput, a batch microwave oven system will suit your needs best. FMT offers solutions ranging from indexing systems, to processor ovens, and mini-batch ovens for those with limited space.

Batch Ovens

FMT’s batch ovens are widely popular among food processors for the efficiency and control they bring to the process. Whether the installation requires a throughput of 13,000 lbs. of product per hour, or the flexibility of a smaller final yield, we can help reduce total production costs by reducing on-hand inventory requirements and increasing final yields. Our systems enable precise tempering and control of final product temperature.

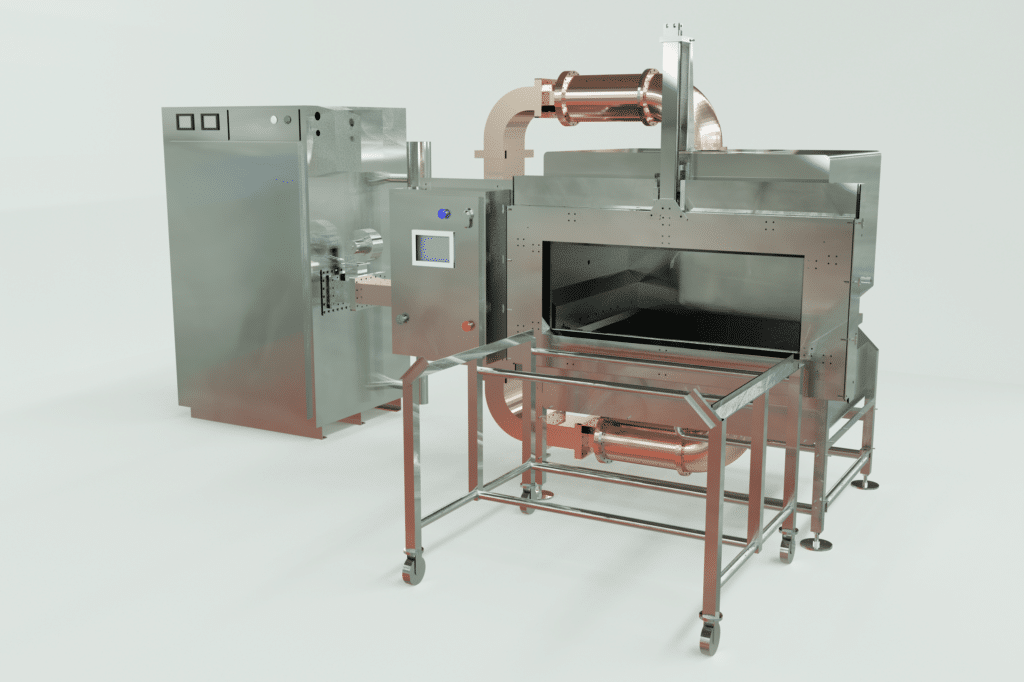

Processing Ovens

Ferrite Microwave Technologies precise batch processing ovens are customized to fit exact requirement needs. We’ve delivered units to meat processing operations, sausage kitchen owners, commercial bakeries, and other frozen and prepared food manufacturing environments. Our batch processing microwave oven systems provide uniform heating for consistent and effective tempering for a variety of products.

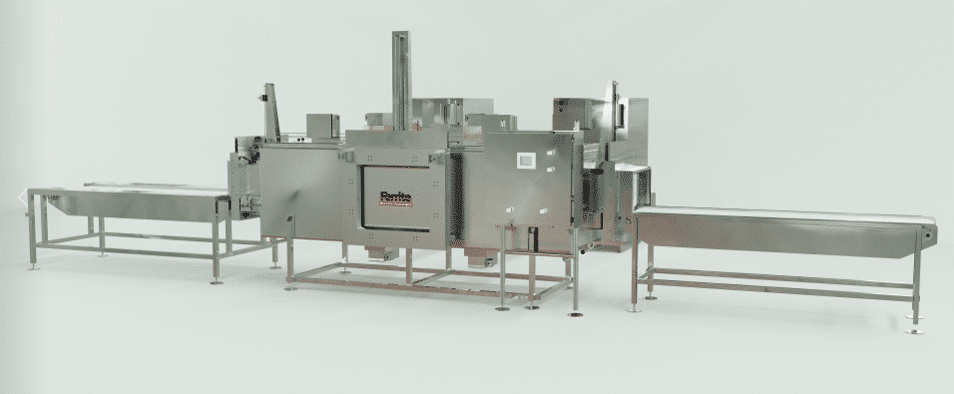

Indexing Ovens

Our indexing batch microwave oven complies with European emissions standards and will temper up to 13,000 lbs. of product per hour. The system consists of a 4x4x8 foot long cavity with an internal oscillating conveyor. It comes equipped with conveyors for loading and unloading product on one or both ends. Indexing ovens are available with up to two 75 kW transmitters for 150 kW of total power.

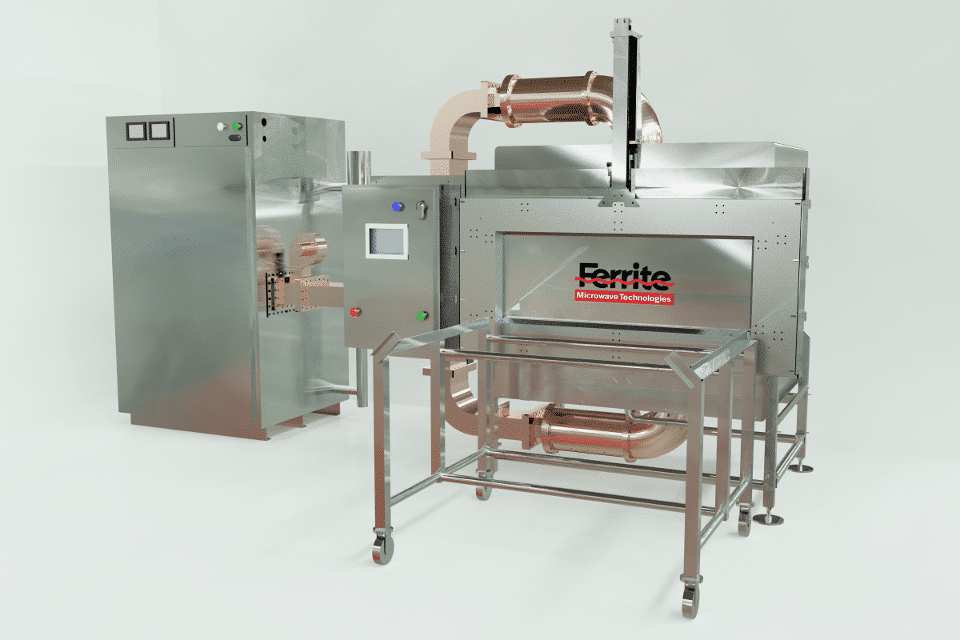

Small Batch Ovens

FMT’s small batch ovens offer speed, control, convenience, and cost savings. Small batch microwave oven systems are suitable for relatively low-volume applications. These style systems are ideal for fast-moving food preparation environments, like that of a cruise ship. Uniquely, our smaller sized ovens utilize rotary tables. Typically, this system comes with a standard 35 kW of power. It is controlled by a PLC processor.

Batch Microwave Oven Systems: Loading & Operation

To fully understand how a batch oven microwave system works, we welcome you to watch this video. This visual demonstration shows the loading and operating procedures for our MIP10 Processor Microwave Oven.

Are Batch Microwave Oven Systems Safe to Use?

Yes. To fully understand their safety, it is important to recognize the difference between ionizing vs. non-ionizing radiation.

Microwaves are a form of non-ionizing radiation, which means that they create no lasting effect. This is in stark contrast to ionizing radiation (like that emitted from radioactive materials). Ionizing radiation permanently changes exposed material, whereas microwaves are far less dangerous and harmful.

Above all, when you turn off the system, everything is exactly as it was, except the material you treated, which is now at the desired temperature.

In closed batch microwave oven systems, door sensors with automatic shutdowns ensure that while the system is running users are not exposed to electromagnetic energy. FMT systems provide a safe operating environment.

Our Batch Microwave Systems

Ferrite Microwave Technologies offers three standard microwave processors for batch tempering. We design and manufacture all systems with three primary factors in mind – Generation, Application, and Control.

MIP4: Mini Batch Type, 35 kW, Low Volume & Laboratory Use

MIP8: Indexing Type, 150 kW, CE Compliant, Large European Install Base

MIP10: Batch Processor Type, 75 kW, Used in Food Processing Plants

Although these 3 systems are our standard offerings, we customize every system we build to suit the customer’s facility and requirements. We are happy to manufacture custom cavities and applicators to fit non-standard requests.