Most of the pre-cooked bacon in the world today is prepared with large-scale microwave processing systems, such as our advanced MIP11 bacon processing system. As the inventors of the modern microwave bacon system and with the largest installed base we have the experience needed to support your process. We’ve found that most have questions about the system, components, and the process as a whole. Here, we’ll break it down: the history, bacon processing variables, and the components that make up our MIP11.

Microwave Bacon Processing: A Quick History

The 1970s

- In the 1970s, microwave bacon processing equipment was first introduced.

- The equipment was relatively modest, with slicing at low speeds (roughly 200 slices per minute).

- At this time, the available microwave power levels were 100 kW.

- Packaging equipment completed by hand.

The 1980s

- In the 1980s, larger food corporations saw an opportunity.

- These companies saw a growing demand and viewed bacon processing as a lucrative endeavor worth investing in.

- New equipment manufacturers met the growing market demands by introducing newer, faster, and more capable technology.

- Technology and equipment developments included:

- Higher speed, 3-lane slicers (capable of slicing 750 slices of bacon per minute).

- Higher power microwave bacon processing systems (at this time, rated around 300 kW).

- Instead of packaging by hand, automation began. Some systems offered automatic conveyors.

The 1990s

- By the 1990s, installations of microwave equipment reach around 50 units worldwide.

- At this point, equipment and technology advanced even more.

- Advances included:

- Even higher speed slicing at 1,100 slices per minute.

- Even higher microwave power, at an average of 450 kilowatts.

- Case packing turned completely automatic.

The 2000s

- In the 2000s, bacon processing changes considerably.

- As retail packaged bacon is introduced to the public, sales skyrocket.

- Households and fast food corporations widely accept the notion of using bacon as a flavor enhancer.

- Variations of the product change, with slices and bits used as toppings and garnishes.

- Consequently, microwave bacon processing systems reach over 100 worldwide.

- As it had over the previous decades, the technology continues to improve in terms of efficiency, speed, and power.

- Slicing: 2,000 per minute.

- Power: 800+ kilowatts per system.

- Ventilation optimization is introduced.

- All functions (slicing, cooking, packaging) are combined into a more integrated system.

The Market Today

- 2006 retail sales: exceeded $2 billion.

- 2013 retail sales: reached over $4 billion.

- Today: Over 44% of in-home bacon is pre-cooked.

Microwave Bacon Processing Variables

If you’re considering processing with a microwave system, you will want to take note of these critical process variables:

- Ventilation

- Belt speed

- Slice thickness

- Microwave power

- Belly temperature

- Product density on belt

- Number of slices per minute

System Components

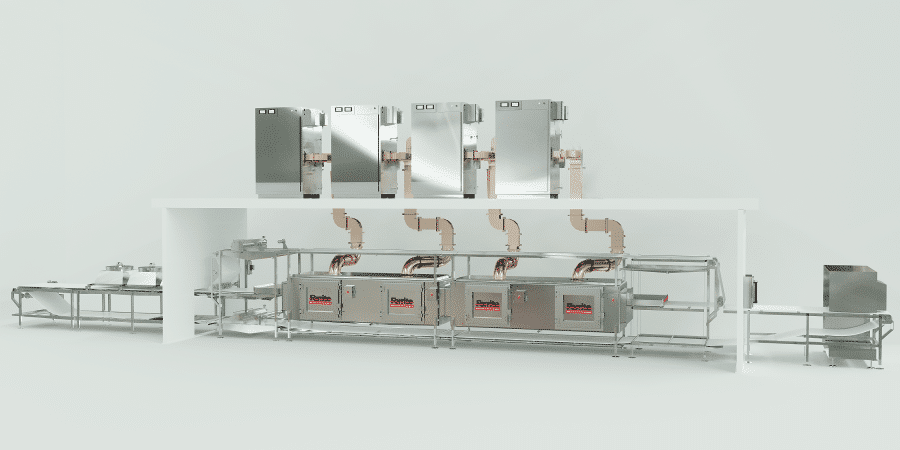

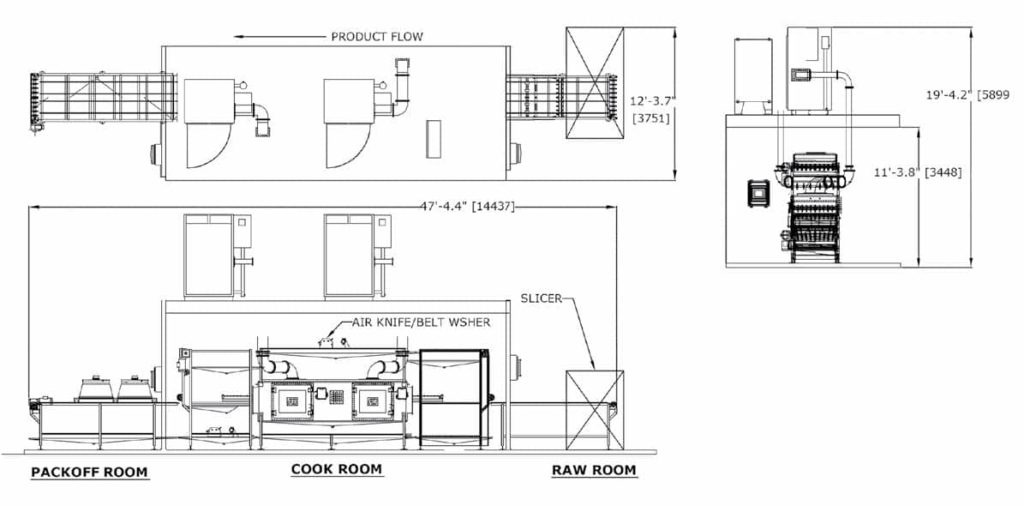

In systems like Ferrite Microwave Technologies MIP11, several components unify for a completely integrated system:

- Cooking Oven(s)

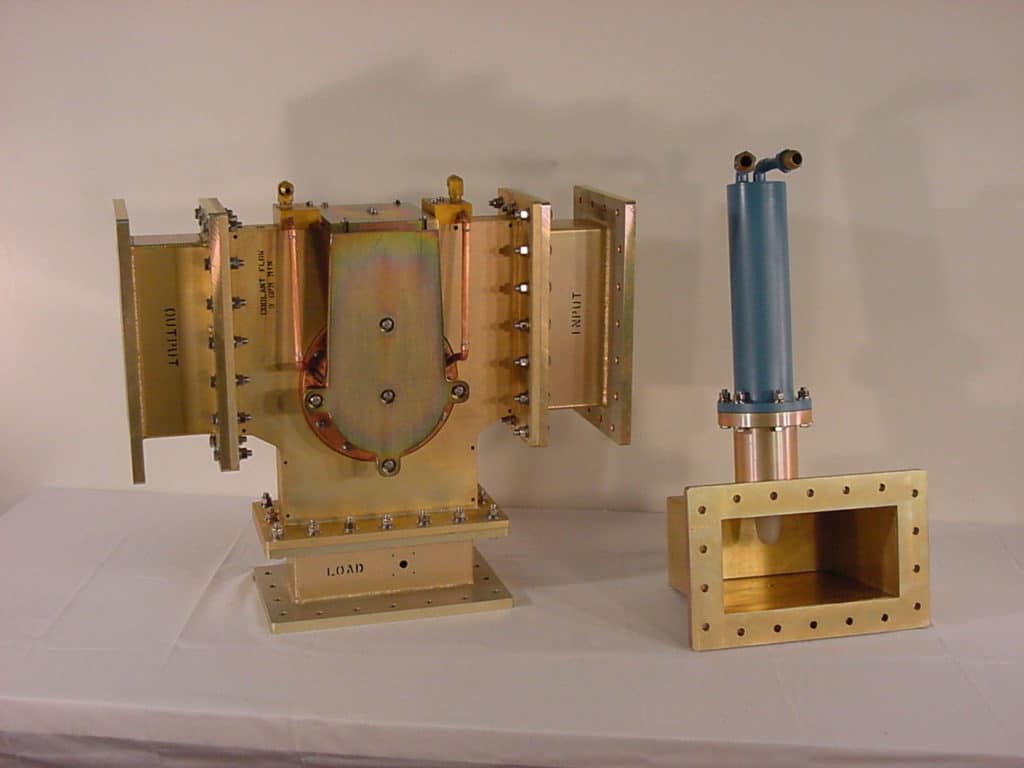

- Power Supply: Generator / Transmitter

- Magnetron

- Circulator

- Water Load

- Applicator

- Stirrer

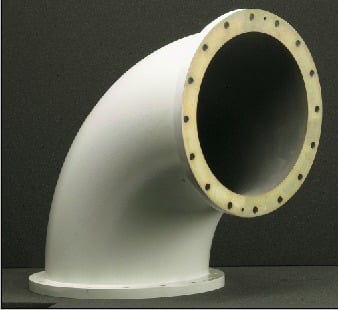

- Waveguides

- Suppression system

- Control box

Why Process Bacon with a Microwave System?

At this point, you may be wondering the reasons why you should process bacon with a microwave system. Ferrite Microwave Technologies has determined four major reasons why. Below, we’ll elaborate on each reason.

1. It’s profitable.

2. It’s easy to do.

3. By-products result in value, not waste.

4. The quality does not get compromised.

Profitability

The use of microwaves to process bacon is more cost effective than other methods. It is a widely popular food, with a demand that continues to surge, year after year.

Easy to do

Bacon provides very good conditions for rapid microwave cooking. It’s thin in cross-section. It also contains dissolved salts (ionic compounds) and has plenty of water content (dipolar molecules). A 100 gram slice of raw bacon contains: 40 grams of water, 45 grams of fat and 833 milograms of salt.

By Products

Nearly all of the by-products of bacon are recovered, sold, or used. The by products of bacon include: grease, fat, end pieces, bits, and rejected slices. Bacon grease can be used as a flavor enhancer. Fat is collected and sold as a flavoring ingredient, to pet food and cosmetic processors. It can also be used for supplemental power generation. Ends and pieces can be fully cooked for use as bits and pieces (as a topping). Rejected slices are reduced in size and sold as bits and pieces.

Quality

The texture of bacon is closely controlled. Fortunately, with bacon processing microwave systems, you don’t have to worry about burning or curling of the edges.

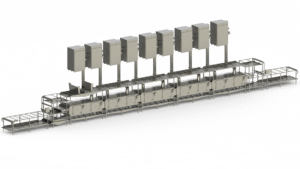

Modular Microwave Systems

Ferrite Microwave Technologies has modular systems to fit your needs. Below are typical specifications. Length includes supression assemblies, but does not include extension conveyors on either end. Expansion beyond 600 kW is available.

| Model (MIP11 Base) | Power | Length of System (ft./m) |

|---|---|---|

| -1 | 75kW or 100kW | 24.5 / 7.5 |

| -2 | 225kW or 300kW | 37.5 / 11.5 |

| -3 | 375kW or 450kW | 50.5 / 15.4 |

| -4 | 525kW or 600kW | 63.5 / 19.4 |

To learn more about Ferrite Microwave Technologies Bacon Processing Systems, please contact our support team.