Ferrite Microwave Technologies (FMT) high power waveguide terminations are designed with rugged construction for reliable performance. FMT terminations are available in various configurations, including: air-cooled, water-cooled, and water-coupled. Ferrite offers most common flanges with all termination designs. Waveguide sizes are available from WR28 to WR2300+. We cover a frequency range of 50 GHz to 50 MHz, supporting the UHF, L, S, C, X, Ku, K, & Ka Bands. As part of our combined product portfolio with Mega Industries, FMT offers an expansive line of high power waveguide terminations. This includes the FXR Dummy Load product line, previously acquired by Mega, and now a Microwave Techniques product brand.

View our 3D Standard Parts CAD Catalog and product data for loads and terminations on the Microwave Techniques website.

High Power Terminations

An overview of Ferrite Microwave Technologies design, engineering, and manufacturing capabilities for high power waveguide terminations:

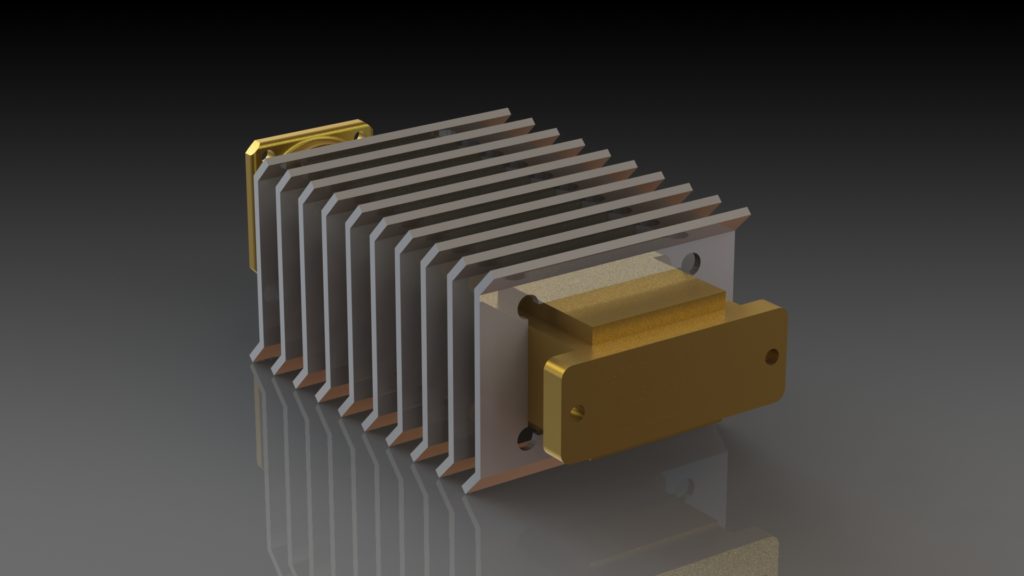

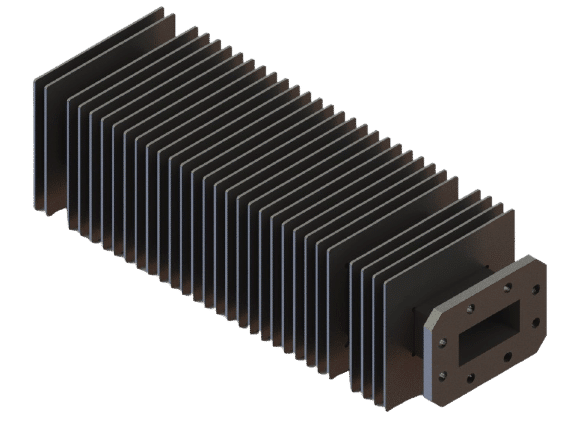

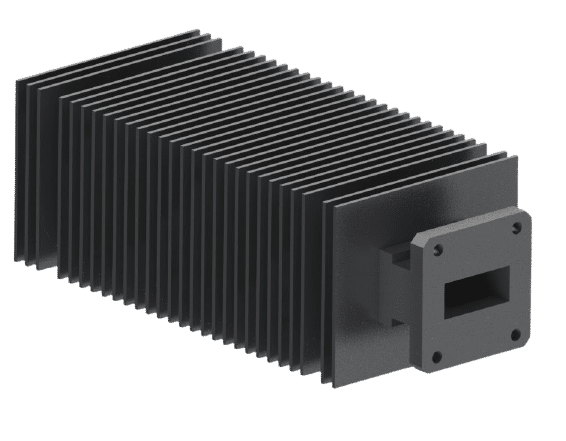

- Finned & Unfinned

- Dry & Water Cooled

- Vacuum terminations

- Custom mounting available

- Custom flange configurations

- Collaboration with Mega Industries

- Air cooled, water cooled, water coupled

- Solutions for low, medium, high, and ultra-high power

- Designed to exceed electrical requirements of MIL-DTL-3954

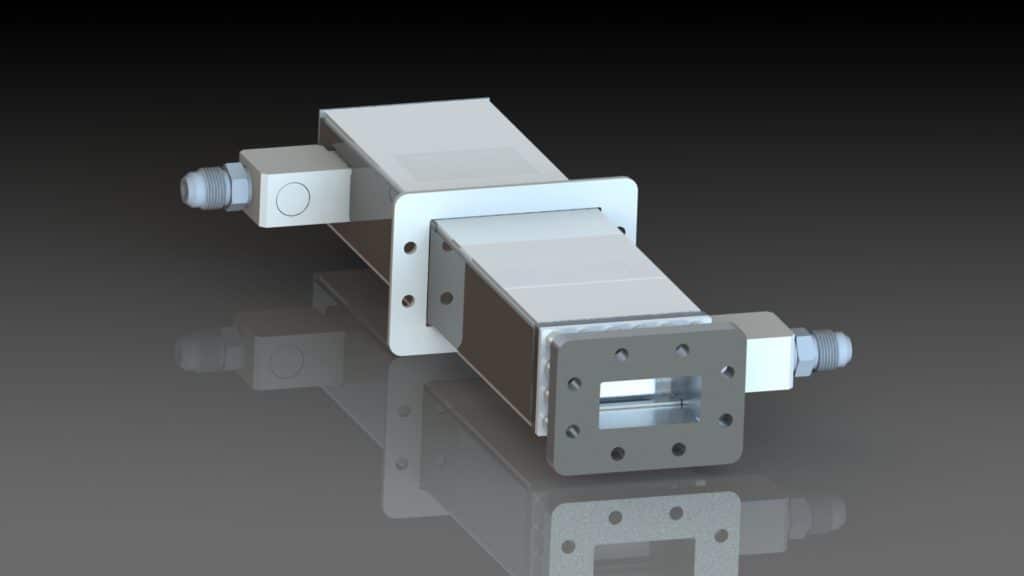

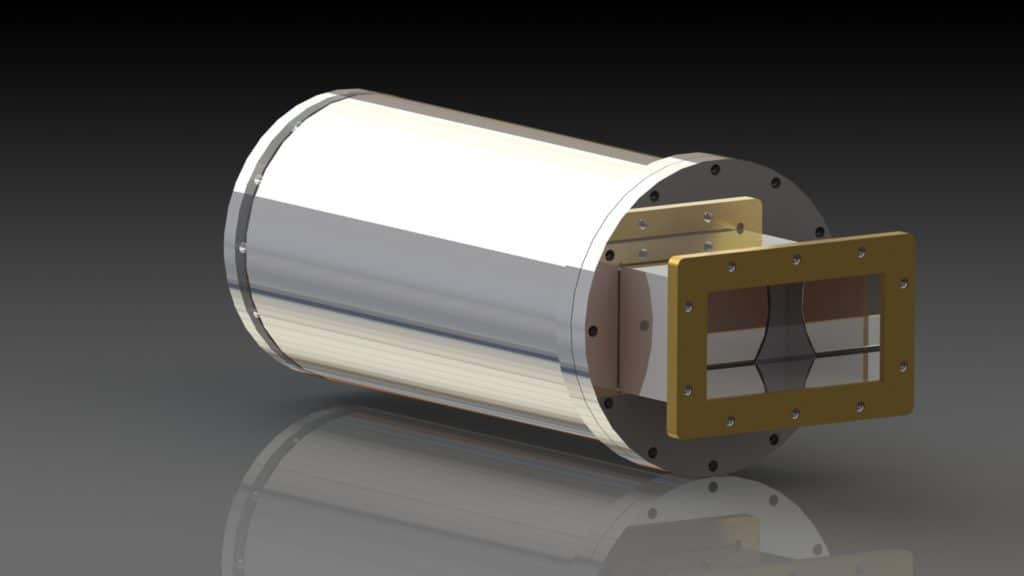

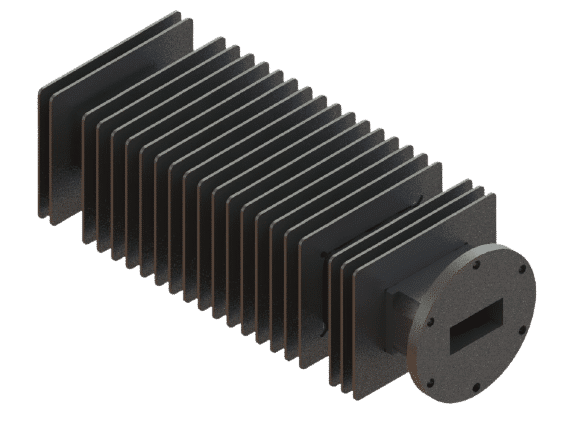

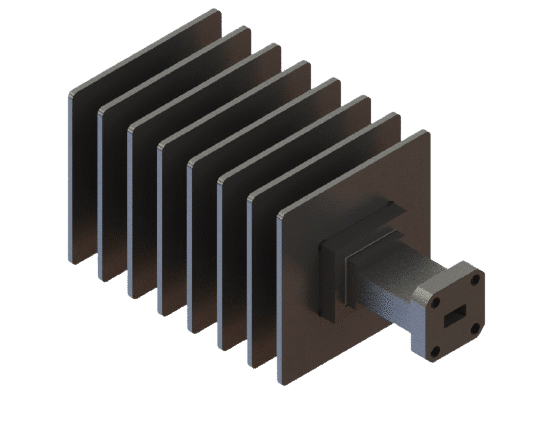

Air Cooled

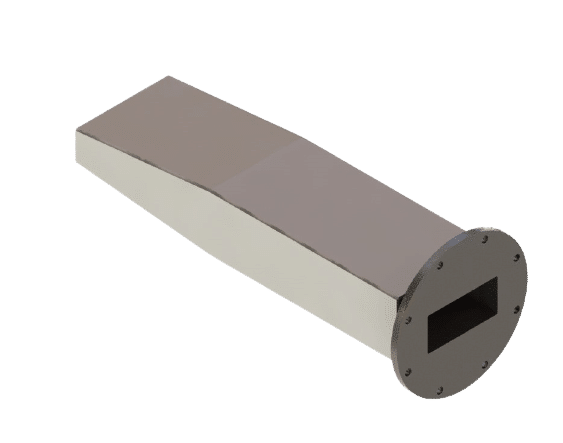

Air cooled terminations are manufactured using the same high power refractory grade ceramic as our high power waveguide terminations. These terminations are great alternatives when the lower power allows for their use as they are usually lighter and smaller in size than high power alternatives.

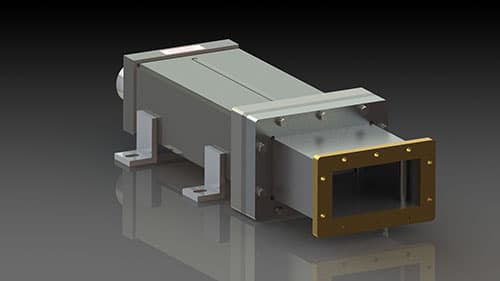

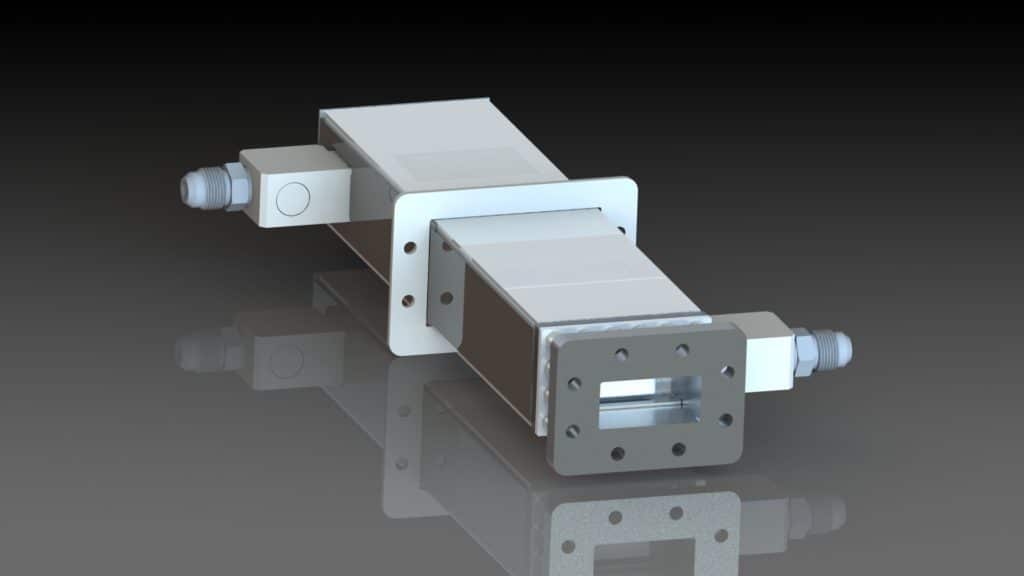

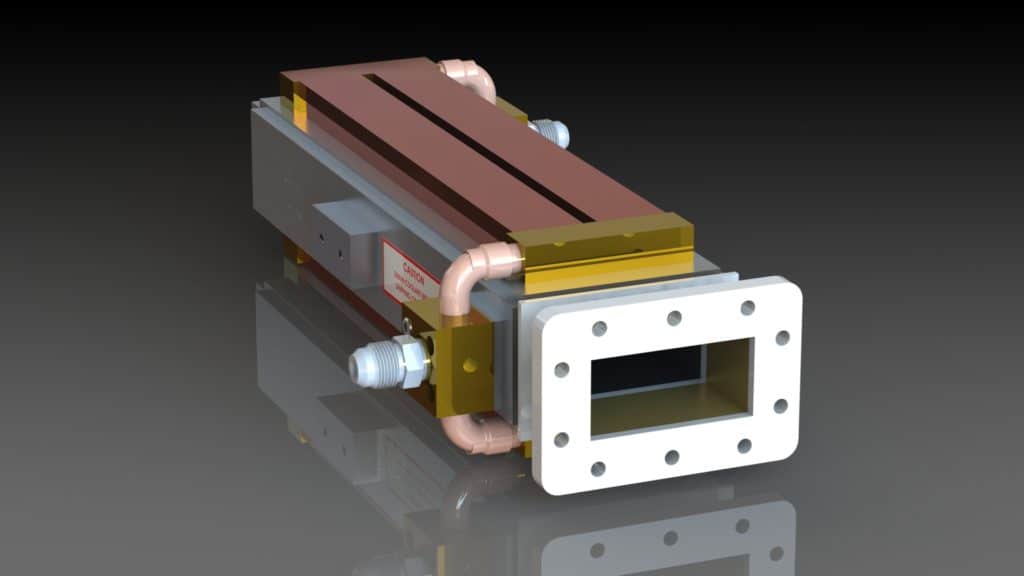

Water Cooled

High Power Water Cooled Terminations provide exceptional power handling capabilities not reasonably attained using dry termination design. Cooling is achieved by the use of internal liquid flow and is an extremely efficient method of dissipating the heat generated by microwave energy.

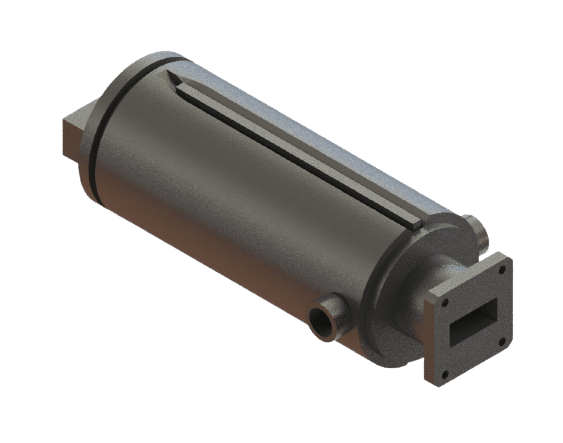

Dry & Water Cooled Terminations

All FMT High Power Dry & Water Cooled Termination designs offer reliability and mechanical strength as the primary concerns. Units available in both finned and unfinned designs. The peak power capability of one of our devices will in general be the same as the connecting waveguide. If desired, water cooling applied to the external surface of these loads greatly increases the average power capability.

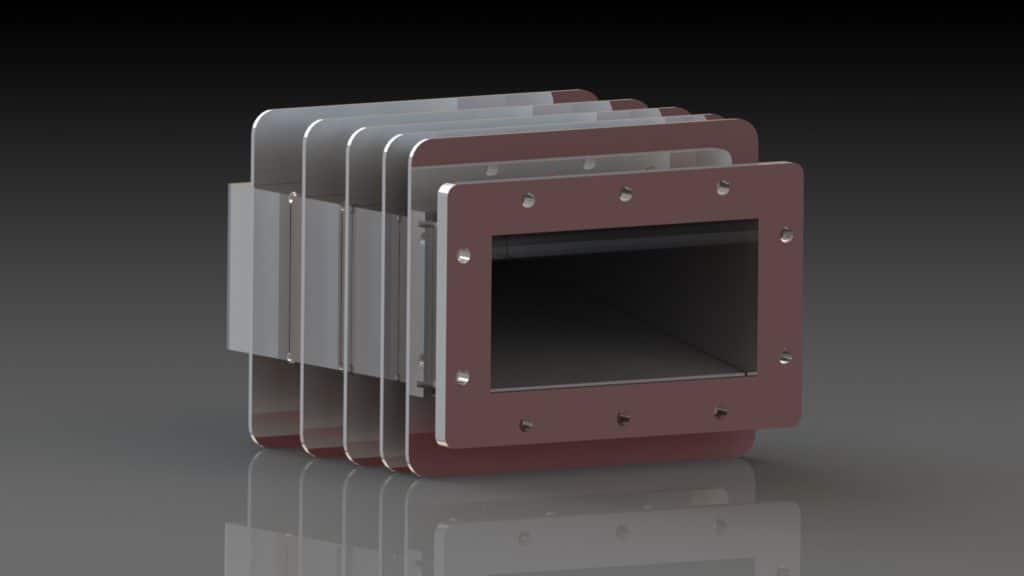

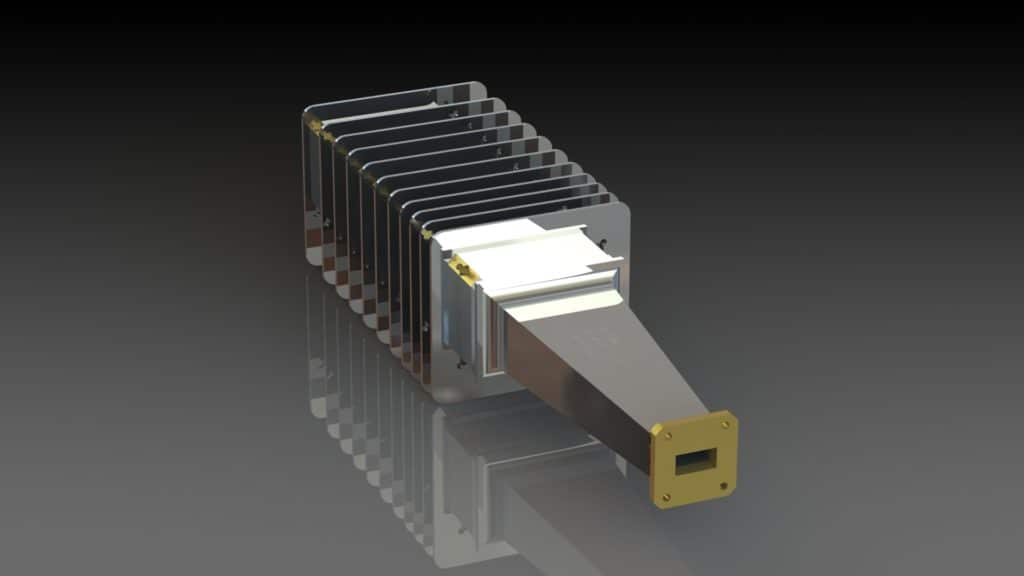

High Power Waveguide Terminations

Our standard line of high power waveguide termination designs satisfy and exceed microwave industry requirements where reliable performance, rugged construction and reasonable cost are the primary considerations. All models we build use an ultra-high temperature refractory ceramic as the microwave absorber. This absorber is then encapsulated within an intimately – fitted and welded aluminum housing which ensures maximum heat transfer at the rated power levels.

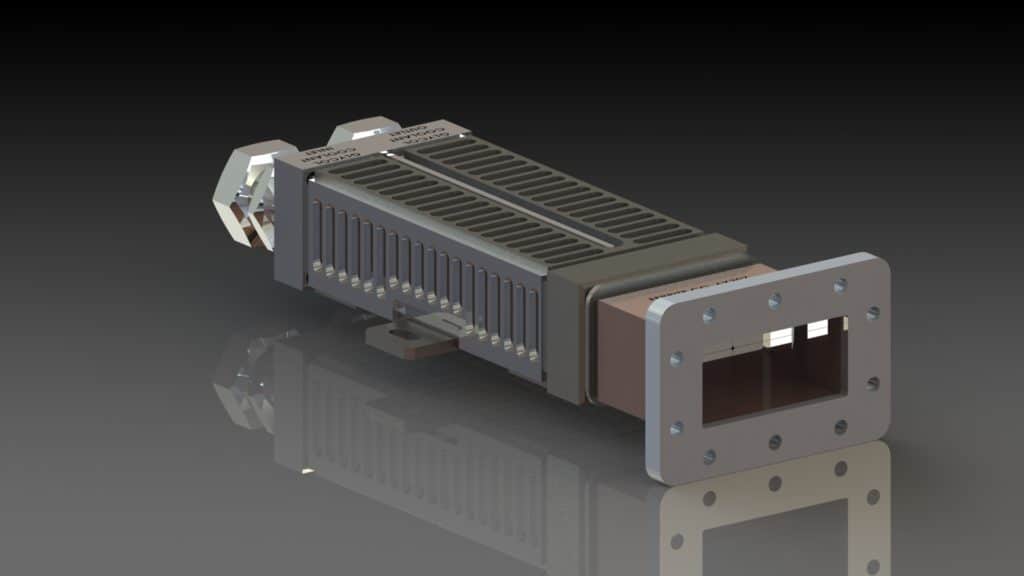

FXR Loads

Part of our high power waveguide termination product portfolio includes the FXR Dummy Loads product line. This includes designs for finned, unfinned, liquid cooled, super-high power, and more. In addition, Mega Industries offers its own line of high-power test terminations, as well as short circuits.

Custom Terminations

Flanges are interchangeable between CPR and UG Types for giving waveguide size. Custom flange configurations and mounting are available. All materials in direct contact with the liquid cooling are designed for compatibility. All welded terminations designs meet or exceed the electrical requirements of MIL-DTL-3954. To learn more about custom terminations, please contact us.