Ferrite Microwave Technologies (FMT) is the global leader in high power waveguide component manufacturing for several industries. As a Microwave Techniques company, we leverage 100,000+ square feet of production space, with 3 facilities across Maine and New Hampshire. Each manufacturing facility uses state-of-the-art maching and testing equipment. Our quality-driven and custom-centric approach allows us to be a dedicated partner for all things microwave & RF.

Manufacturing Capabilities

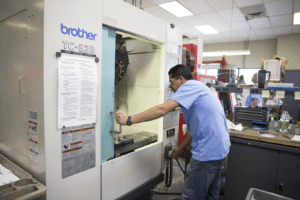

One of the unique aspects of our capability lies in the scope of our captive manufacturing process. Due to the critical role machining plays in component performance and reliability, our waveguide and coaxial piece parts are machined in-house utilizing the CAM files generated directly from our CAD designs and simulations. Secondary operations and all in-process and final testing are performed in-house with the industries latest proven technology.

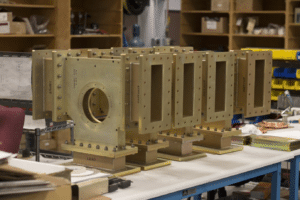

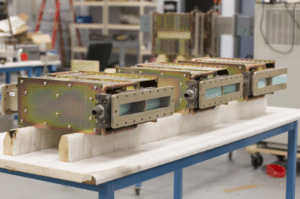

As a group, we have years of experience, innovation and ability to take a rough concept through a successfully delivered solution. We fabricate intricate shapes, incorporate uncommon materials, often times in non-standard waveguide and coax sizes. Ferrite Microwave Technologies offers an array of solutions for elevated power levels as well as custom applications.

Quality, innovation, and reliability are the principles we stand by. As part of our commitment to quality and excellence, we maintain ISO 9001:2015 & AS9100D Certification.

State-of-the-art facilities: Highlights

Each of our manufacturing facilities have the capacity for the largest of projects. The Microwave Techniques group has three large production facilities within 90 minutes of one another in Maine and New Hampshire, USA. We also have a facility in North Carolina for IMS. In 2020, the high power waveguide component manufacturing division doubled its capacity with the addition of a second facility in Gorham, Maine, USA, located directly across the street. We maintain vertical and horizontal machining centers, computer-controlled lathes and E-mills, and several drill presses.

High Power Waveguide Manufacturing

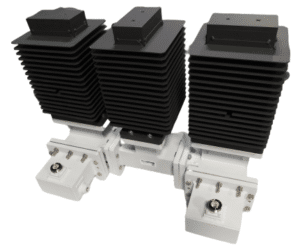

FMT’s expertise is in high power waveguide component manufacturing. Our line of components includes circulators, isolators, loads, windows, rigid waveguides, flexible waveguides, coaxial components, ultra-high vacuum components, and broadcast components in sizes WR28 through WR2300 supporting 50 MHz to 50 GHz, that handle power levels ranging from 5 W to well over 50 MW.

With a design tool library of thousands of models to choose from, our solutions are nearly limitless. We have over a century of combined high power waveguide component manufacturing experience.

To learn more about our engineering capabilities, please click here.

Ferrite has a full complement of mills, lathes, and metal working machines to build all components in house. By having these capabilities, we can do in-process inspections to yield high quality parts without relying on vendor schedules. Our crew of experienced machinists are talented in completing custom machining projects with very close tolerances.

We utilzie state-of-the-art CNC software to create machining instructions directly from the CAD solid models, from which the components were designed. This ensures accuracy and repeatability. To learn more about our high power waveguide component manufacturing capabilities, please contact our support team.