In this post, Ferrite covers the benefits of microwave tempering. FMT also covers the costs associated with other tempering options. But first, we would like to start with an overview of the tempering industry.

Industry Background

Much of the processed meat produced in the world contains a significant portion of ingredients that have been frozen. They must then be thawed or tempered to permit further processing. Hamburgers, sausage, canned meats, and pet foods are product that rely heavily upon frozen ingredients. Frozen prepared foods and portion controlled steaks are manufactured almost exclusively from frozen meat. As such, they must be thawed to permit portioning. So, processing frozen product is a well entrenched process in your industry. However, it is one we would suggest, that isn’t that well understood.

Important Definitions

- Enthalpy – Amount of heat energy absorbed or released during a change occurring under specific conditions

- Thermal Conductivity – The rate at which heat is transferred through a given material

- Thawing – Melting all the ice crystals in a product

- Tempering – There is no standard definition but, usually achieved along the flat portion of the enthalpy curve or so called “heat of fusion”

Thawing Process

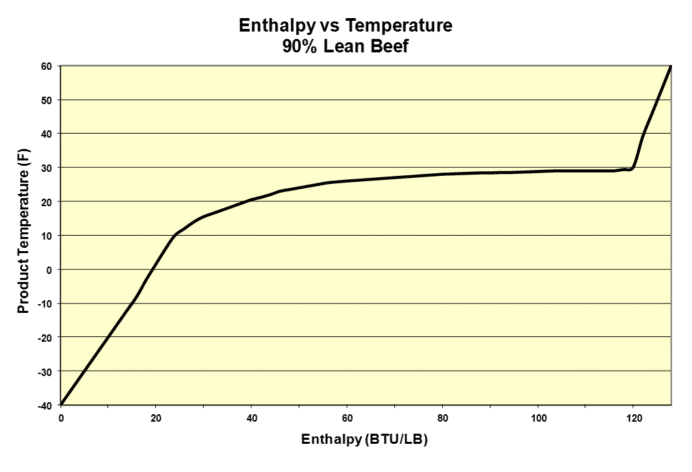

Thawing involves melting all the ice crystals in the product. It typically requires 232 kj/kg of heat to do so with 90% lean beef starting at -18ºC. The enthalpy curve for this product:

Tempering Methods

There are two primary tempering mediums; air and water.

Air thawing

- Boxes are thawed on pallets with air spacers between the layers

- The process can take many days depending on air temperature and velocity

- It can be costly in terms of floor space, drip loss and inventory size

- It can downgrade overall plant hygiene

Water thawing

- Standard practice for many fish products

- It is faster and consumes less space than air-thawing

- Regulations concerning water usage and waste water quality are making this a less than desirable process

Traditional Tempering Costs

The cost factors that are both quantifiable and controllable fall into three categories: Drip loss, bacterial growth and water.

Drip Loss

In boxed beef it is in the order of 5% with a protein content of 10%. Assuming a 27 kilogram block, this represents 0.14 kilograms of protein. Obviously, drip loss represents a cost to the processor through yield reduction. It also affects product quality because of color and flavor deterioration.

Bacterial Growth

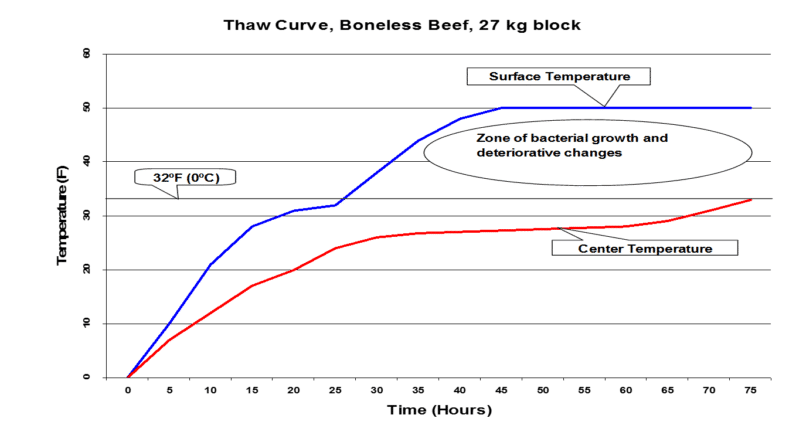

Heat transfer (and thaw rate) is dependent on thermal conductivity. Frozen lean beef has a conductivity of 5.0 Joules/hr-mm-°C and Thawed lean beef has a conductivity of 2.0 Joules/hr-mm-ºC. One consequence of this is as thawing proceeds into the meat block, the thawed outer layer limits the heat flow to the core because it acts as an insulator. The figure below is a beef block thaw curve:

As you can see, elevated surface temperatures over an extended period of time create a real risk to the processor of product contamination.

Water

With water usage, a significant cost is associated with water thawing. Waste water treatment is expensive as water and drip loss clear-up can use a considerable amount of water. In many parts of the world — and likely even more so in the future — water usage is or will be a considerable cost to the processor.

Benefits of Microwave Tempering

There is no standard definition for tempering. However, it is usually achieved along the flat portion of the enthalpy curve or so called “heat of fusion.”

Microwave heating can typically raise product temperatures to around -3°C +/-1°C. However, it should not be used to pass it through the phase change of water. It is difficult to control past that point. Tempering is successfully employed as an alternative to thawing. The attendant problems of drip loss, bacterial growth and other deterioration changes in many processes. Microwave tempering also can improve down stream processing. In particular, those utilizing slicing, grinding, and dicing, by providing uniformly conditioned meat blocks.

The benefits of microwave tempering include:

- Elimination of plastic liner entrapment

- Reduced inventory

- Improved response time

- Heat balance control

Types of Microwave Tempering Systems

These types of systems number well over 500 around the world. They can achieve temperature control of +/-1ºC throughout a product through precise energy input. The cost of microwave tempering 1 kg of product from -18°C to -2°C is around US$0.0. Microwave tempering costs are well documented:

- Electricity @ US$0.10/kWhr

- Cooling water (recycled)

- Maintenance (magnetron life of 4,000hrs)

- Depreciation @ 3 year

The Benefits of Microwave Tempering: Conclusions

The true costs of air and water thawing are not often taken into consideration by the processor. Thawing can be very costly. Thawing should be considered only when a total elimination of ice crystals is required. Microwave tempering should be used in conjunction with many processes, particularly those that involve slicing, grinding and dicing. Precise temperature control to +/-1°C and temperatures from -18°C to -3°C can be achieved in 3 minutes or less. Microwave tempering is no more expensive than air or water thawing when comparing actual costs. In fact, it is often less expensive when full cost accounting is properly employed.

To learn more about the benefits of microwave tempering, please contact our support team!