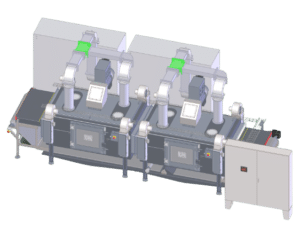

Ferrite Microwave Technologies works with clients to configure new, existing, or custom microwave systems to meet your exact requirements. All FMT systems are customized to meet specific customer specifications. Ferrite meets these requirements throughout the entire process, from design, modeling, and engineering, to manufacturing and installation.

Custom Systems Design: Virtual Modeling

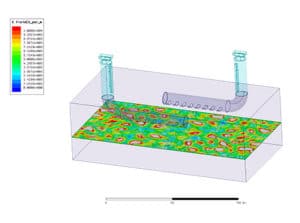

Bringing the state of the art simulation tools and core engineering expertise from our components group allows the optimization of feed networks and energy application to the cavity. We simulate various feed technologies, giving the power distribution data for the product in process. This data allows the mitigation of hotspots within the process by careful applicator placement and design or manipulation of the cavity geometry.

Simulation tools allow the replication of real world problems. As such, we offer methods to address these issues in the simulation domain before offering realistic solution in the hardware.

- The design of optimum input, output and inter-cavity suppression components in simulation allow the design of the smallest form factor possible while maintaining the safety requirements of the system.

- An excellent tool for the visualization of the energy within a cavity gives prospective users a positive indication of how their product will behave within a microwave system.

Technical Expertise & Proven Designs

Our designs have been refined and tested over decades of installations dating back to the birth of the industry.

In conjunction with Raytheon, our founders set the standards for performance. These same standards define the parameters for industrial microwave systems even today. Our mechanical engineering staff is careful to ensure that improvements now and in the future do not impeach the reliability we stand for, or the trust our designs have inspired in our customer base.

Design, Engineering & Customization

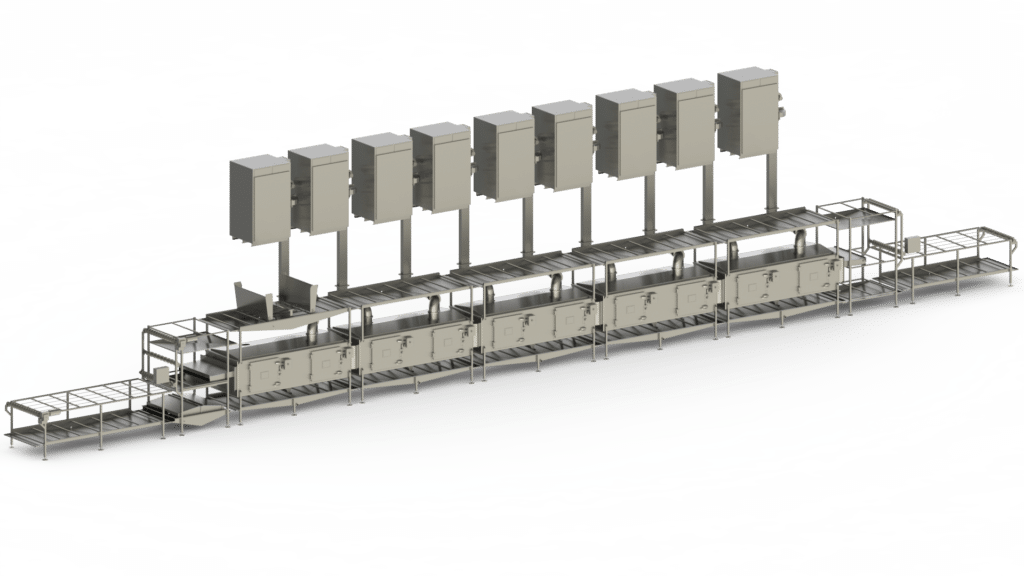

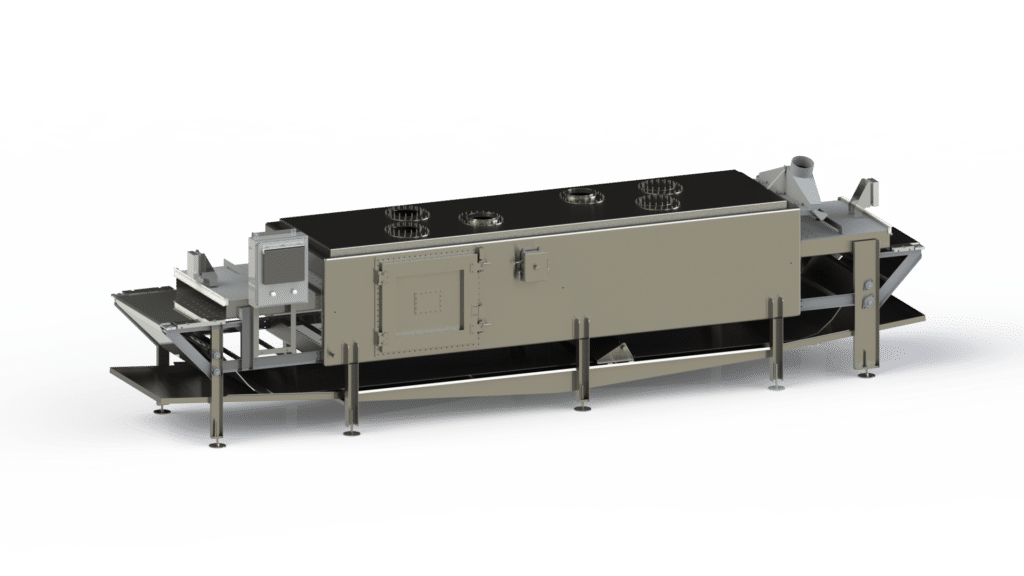

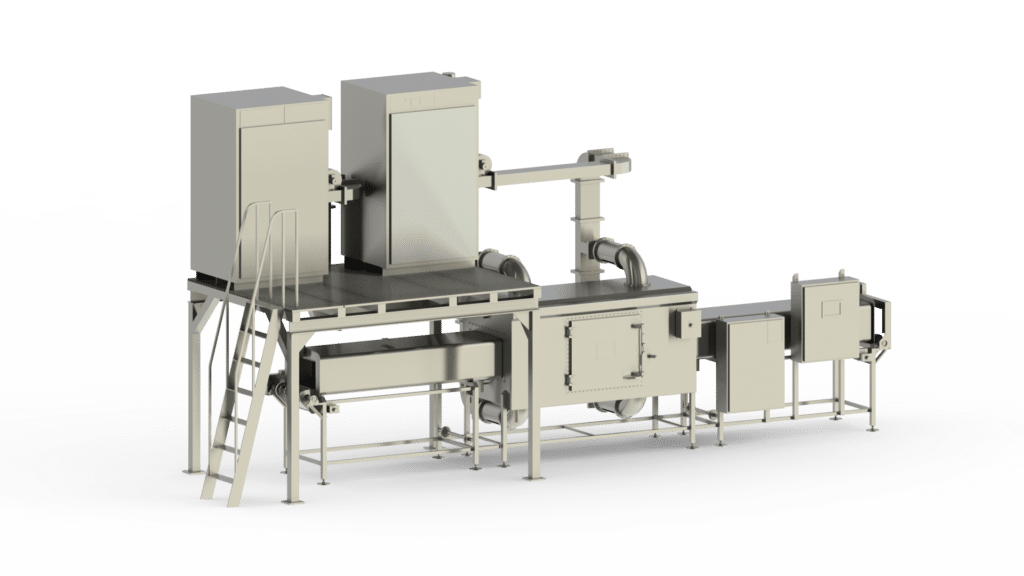

Ferrite Microwave Technologies works with clients to design, model, engineer, manufacture, and install custom microwave systems to meet a number of different requirements:

- Compatibility with new facility floor plans and expansions

- Material handling changes to fit new or existing supply (low bed, boxes, fine grain)

- Local industrial electric supply conversions for facility relocations

- Adjustments to meet governmental regulation and compliance

- Custom line additions like slicers, blowers, washers, dryers, mixers and conveyors

- Design work for sanitation requirements specific to one application

Our microwave and mechanical engineers are available to help you design a system to suit any application, any constraint.

To learn more about our modeling services and custom microwave systems, please contact our support team. We look forward to learning about your products, application, and developing a system to fit your exact requirements.