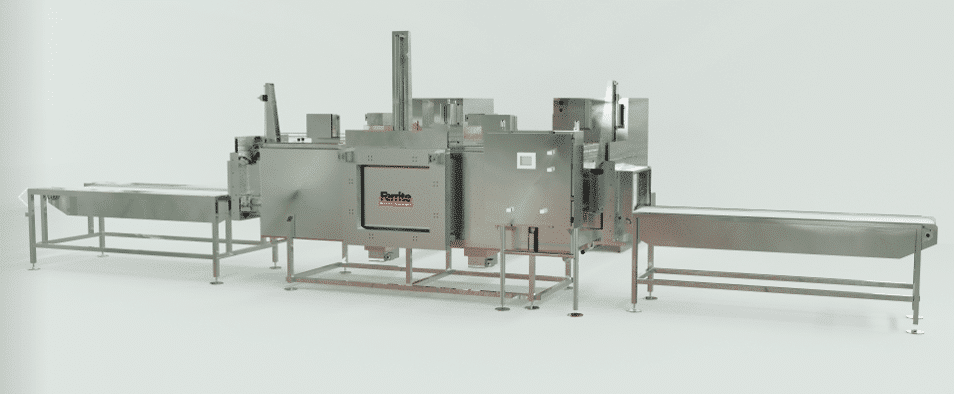

Ferrite’s Food Tempering Tunnel Microwave System (MIP8) is an indexing (with doors) microwave processing system for mid to high volume food applications. The MIP8 tempering tunnel is fully compliant with European emissions standards, even in the ranges between 896MHz and 928MHz. This microwave processing system is able to temper up to 13,000 pounds (5,897 kilograms) of product per hour.

A Complete Food Tempering Tunnel Microwave System

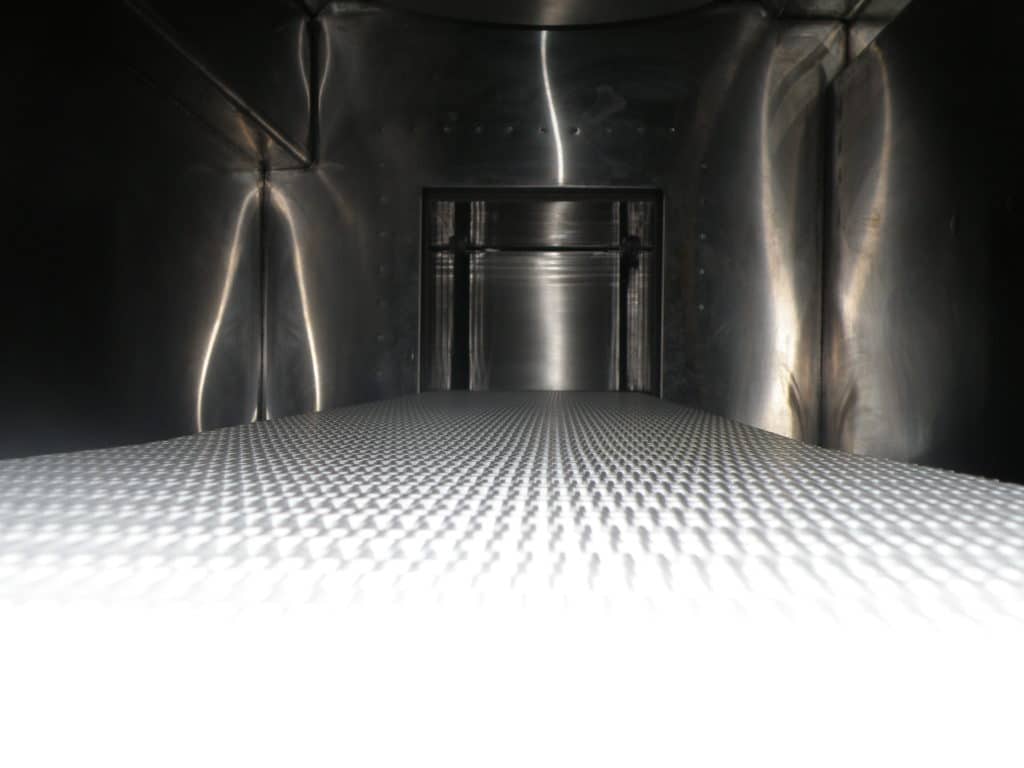

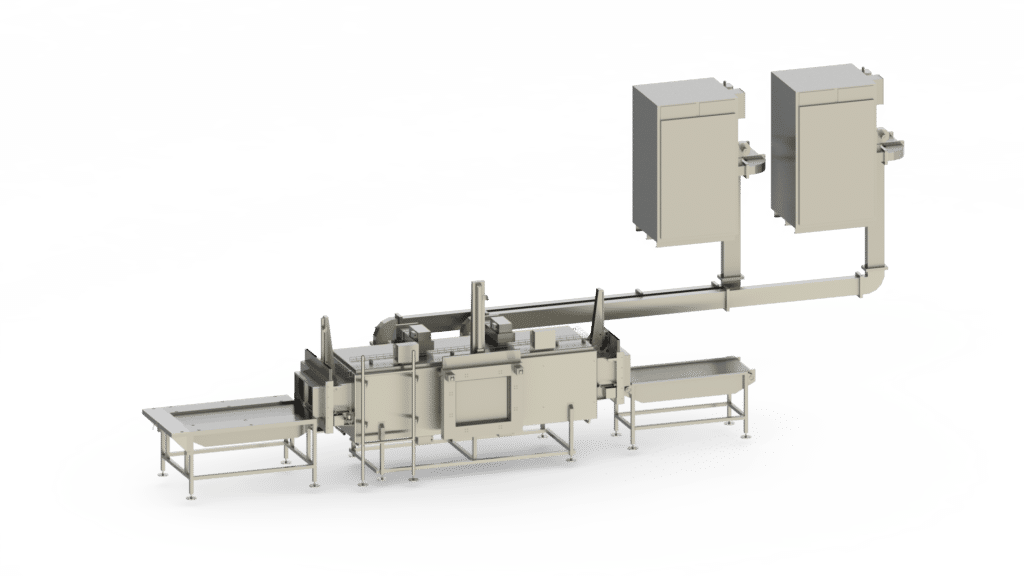

The basic MIP8 system consists of a 4-foot by 4-foot by 8-foot long cavity, with an internal oscillating conveyor, a loading conveyor, and an unloading conveyor. Precise final product temperature control is maintained with simple time and generator power adjustments. The food tempering tunnel is able to utilize up to three dependable FMT generators.

The MIP8 system is capable of greatly reducing tempering time of frozen meat, fish, poultry, fruit, and bakery products. It can improve your food processing time from days to minutes. With the MIP8 tunnel microwave system, you can temper up to thousands of kilograms of zero degree Fahrenheit (-18 degrees Celsius) product per hour.

Simplify the Tempering Process

The MIP8 simplifies the food tempering process. It eliminates tempering rooms and racks, along with the resulting sanitation issues and brings precision to your food processing procedures. Microwave tempering gives control over the production process and helps plan both input and output production on a daily, weekly or monthly basis.

Product quality and yield improves, and drip loss minimizes. Flavor and protein compounds remain in the product and are passed along to the consumer. Controlled temperature increase and predictable final temperature ensures processing flexibility. Microwave tempering enables precise control over product temperature for further processing.

Tempering with a microwave tunnel improves processes such as: slicing, forming, grinding, dicing, and molding.

How Does a Tempering Tunnel Microwave System Work?

Tempering tunnel microwave systems transport product through a tunnel, evenly applying microwave energy to product inside. A 20-inch wide positive drive, articulated belt loads material onto the cavity conveyor and into the tempering cavity. After the loading step completes, cavity doors shut and microwave tempering automatically begins.

While in the tempering mode, the cavity conveyor oscillates the product back and forth to ensure uniform heating. Once the tempering cycle is complete, the doors open and product unloads onto the exit conveyor.

Benefits of Food Tempering Tunnels vs. Alternative Methods

Alternative methods to tempering food usually involves larger spaces. Entire rooms are dedicated to tempering. Usually, these spaces are filled with racks, which may make handling and processing more arduous than simply utilizing a tunnel.

- Space: no need for dedicated tempering rooms or bulky racks

- Processing Flexibility: tunnels allow for tempering on demand

- Safety & Protection: less process time, fewer handling sequences, less overall risk

- Final Temperature: systems such as the MIP8 enable predictable temperature control

- Peace of Mind: ability to remote troubleshoot systems via Ethernet access to PLC controls

- Superior Technology: industry-proven, user-friendly FMT system software and Allen-Bradley controls

MIP8: Frequently Asked Questions

To help you better understand our Food Tempering Tunnel Microwave System (MIP8), we’ve compiled answers to some frequently asked questions. The team at FMT is always on standby to answer any additional questions you may have.

Does FMT customize microwave systems?

Yes. FMT modifies and customizes system designs to meet specific customer requirements.

How does one clean the MIP8?

The MIP8 oven and generator are both manufactured with stainless steel. The processing oven and the conveyor belt are wash-down safe.

Are microwave tempering tunnels safe?

Yes. FMT food tempering tunnel systems have interlocking access doors on the microwave transmitters. The process ovens meet applicable government safety standards. Uniquely, the MIP8 tunnel meets CE compliance.

What are some other unique features?

The unit features arc detection, optional light curtains on either end of the tunnel, and emergency stop buttons. A two button gate lowering function provides extra protection. Check out this data sheet for more information!

Other questions? Feel free to reach out to us to learn more about the MIP8 or other tunnel systems.